A guy here in town said i could use his Gehl 41 PTO mill so i'm going to do that till i can find one, but i need a larger screen for it so i can crack corn for chicken feed. It has a 1/2" screen now and its making mostly dust and pebbles out of corn, would i need a 7/8" or 3/4" screen for scratch feed???

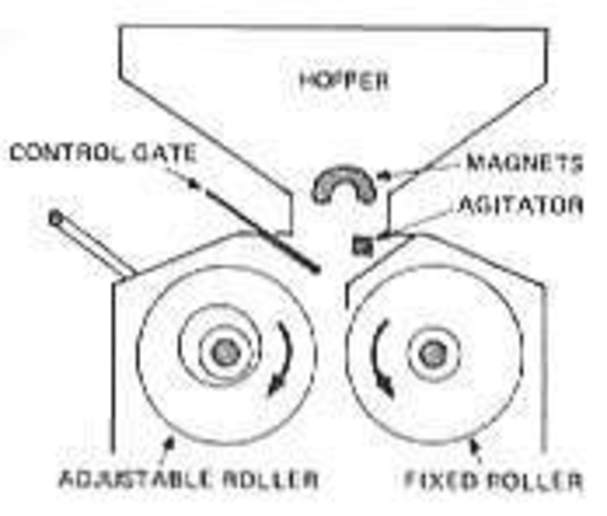

Also what is better for making chicken feed, a hammer mill or a burr mill? I'm thinking the hammer mill would be faster and the burr mill would be hard to find plates for when they wear out??

Also what is better for making chicken feed, a hammer mill or a burr mill? I'm thinking the hammer mill would be faster and the burr mill would be hard to find plates for when they wear out??