Updating the information we found out.

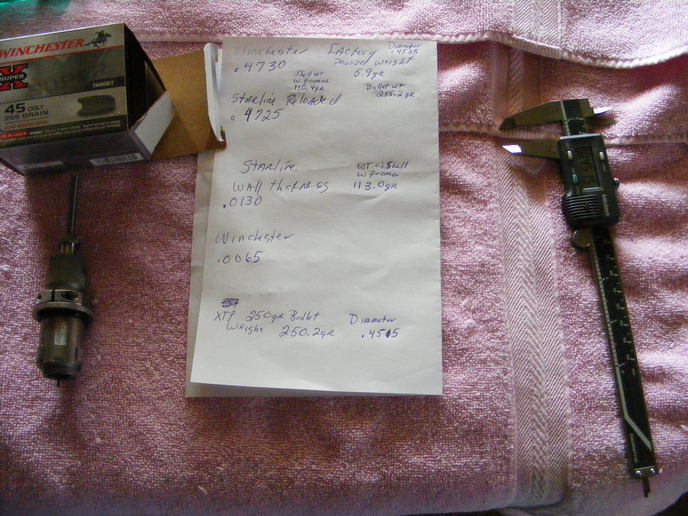

We pulled apart the new winchester 255 gr lead ammo, and the following was found.

Winchester ammo non fired

1. outside diameter of shell case .4730

powder weight from factory 5.9 gr.

bullet weight 255.5gr.

lead bullet diameter .4535

brass wall thickness .0065 in

weight of shell w/primer only 110.4 gr

2. Starline brass

Outside diameter of shell case .4795

bullseye powder reload weight 6.0gr

weight of Hornady XTP HP 250.2 gr.

Bullet dia. .4515

brass wall thickness .0130 in.

weight of shell w/primer only 113.0gr.

** Bullseye powder used per Hornady reloading book is at 6.0 gr of powder,which is the mid way loading range. It ranges from 5.7 gr- 6.0 gr-6.3 gr-to 6.5 max load for a 250 gr bullet.

The book also says the outside diameter of the shell is .480 diameter.

The Hornady reloading die for sizing and de-priming, measurement inside where the case is resized is .4755. This is right to their specs.

The measurement in the weight is off our RCBS electric powder scale-calibrated and double checked for weight on the above findings.

Measurments was from our digital calipers.

The reasons for our problems occuring is the brass on the Winchester shells is the wall thickness is too thin and even when resized,the inside diameter of the case is too large for the .452 bullet, thus allowing the bullet to drop inside the case.Rather than having it pushed in by the reloading press. It seems as though Winchester on this particular brand of bullet used a bigger diameter bullet because it is lead only projectile.This and the fact the case is thinner, it allows the XTP bullet .452 dia. to fall into the shell when placed on the top by hand.

the following steps are what we always do when reloading,

1.Clean used cases with vibrating tumbler and media

2. De-prime and size cases,measure all cases for OAL and Diam

3.Clean primer pockets,reprime cases and add very small bell to

end of case.

4.weigh powder, add to shell.

5. put bullet on top of shell by hand.

6. put shell in press, push bullet into case to

overall length per book specs.

7. crimp shell to bullet, and seal primer and

bullet with ammo sealant.

8. store in case ammo container with tag on it for all the specs of powder charge, date, and all other information.

It should also be noted we are using a single stage reloading press.

So to sum it up, yes Winchester brass on this time is by far thinner and is the cause of the problems we have had.It is not the dies fault, nor operator fault.

Thanks for the ideas and help.LOU