I need another valve to run hydraulics out of the front end loader on my NH3930. It has open center hydraulics.

Right now everything runs off the two rear remotes. If both valves are open, the fluid goes the easiest route, instead of where you want it.

If I put a 6 port divertor valve in the tree spade circuit to run the grapple, when I go to clamp hard on something, the fluid will circulate through the loader, not giving me full pressure.

I want to be able to move/contol the loader and clamp at the same time. Can this be done?

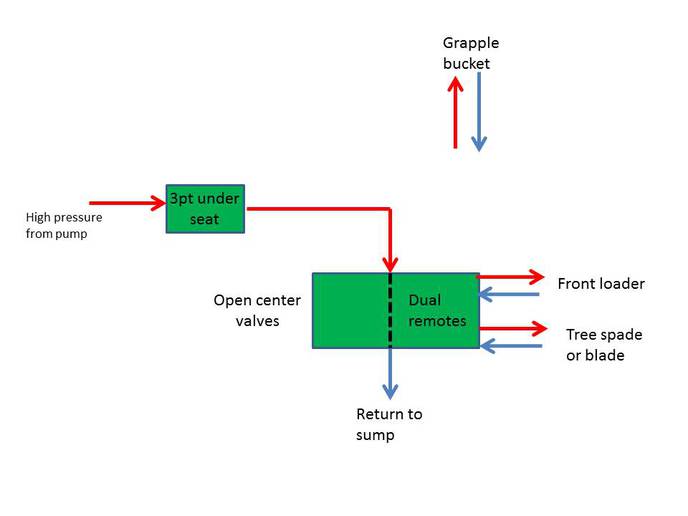

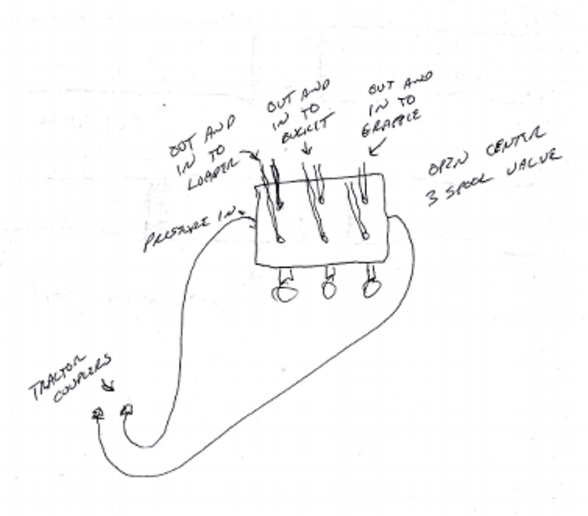

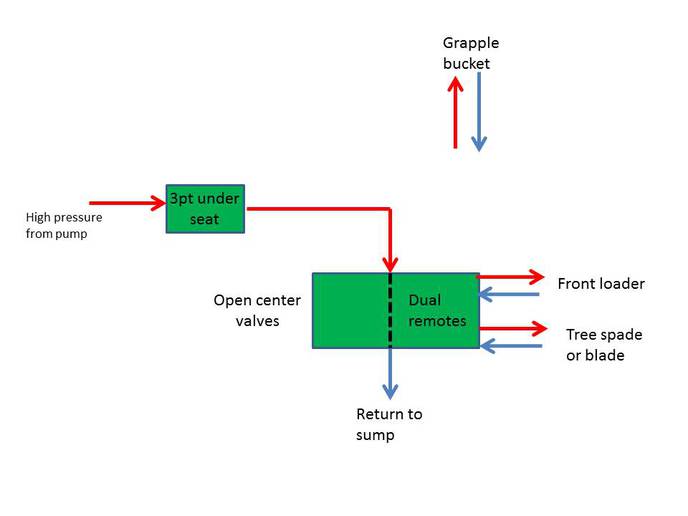

I attached a quick drawing of the hydraulics, the way I understand them.

Right now everything runs off the two rear remotes. If both valves are open, the fluid goes the easiest route, instead of where you want it.

If I put a 6 port divertor valve in the tree spade circuit to run the grapple, when I go to clamp hard on something, the fluid will circulate through the loader, not giving me full pressure.

I want to be able to move/contol the loader and clamp at the same time. Can this be done?

I attached a quick drawing of the hydraulics, the way I understand them.