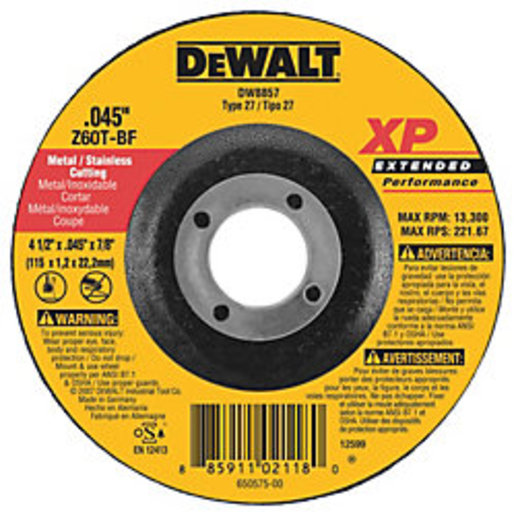

Stopped at Lowes after church and picked up a cut-off tool. First thing I realized was that my little pancake compressor did not have enough volume to run this very long. Don"t have any other pneumatic tools other than some nailers so have not had that as an issue before.

Alternated running the cutter and whacking the slits with a BFH and cold chisel. Probably did not take more than 15-20 minutes to get the old one off. Put the new sprocket on with a shoulder bolt (grade 8), anybody have any issues with that approach. The "rivet" or pin that was called out in the parts book is no longer available from NI. Any real reason to shop around for a roll pin as some of you think should have been used in this application?

Filled the spreader up and took it for a spin. Seems to be working fine. Now probably have another 2 loads to take care of this afternoon.

Attached a few pictures. Thanks for the help on this.

Kirk

Alternated running the cutter and whacking the slits with a BFH and cold chisel. Probably did not take more than 15-20 minutes to get the old one off. Put the new sprocket on with a shoulder bolt (grade 8), anybody have any issues with that approach. The "rivet" or pin that was called out in the parts book is no longer available from NI. Any real reason to shop around for a roll pin as some of you think should have been used in this application?

Filled the spreader up and took it for a spin. Seems to be working fine. Now probably have another 2 loads to take care of this afternoon.

Attached a few pictures. Thanks for the help on this.

Kirk