Geo-TH,In

Well-known Member

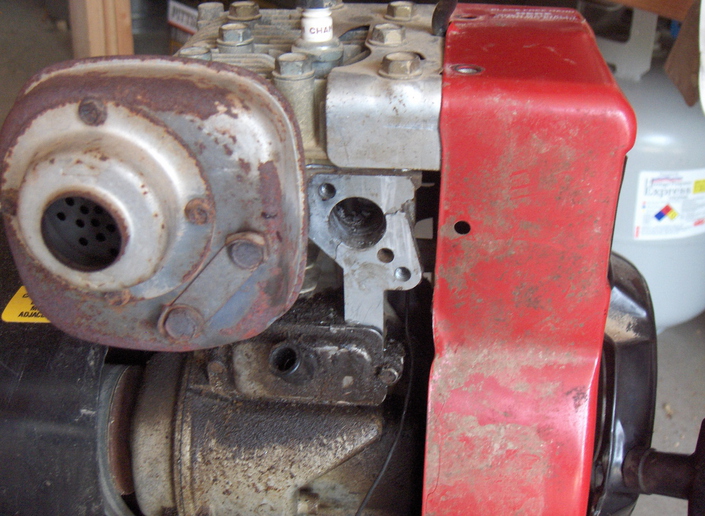

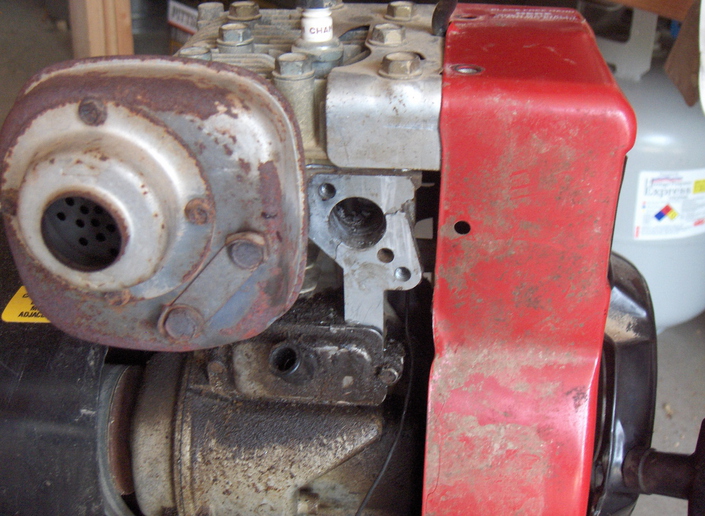

Is there a glue that is better than JB? JB is good up to 230 degrees. I used it to glue the intake back together. Motor works fine, however the temps are way north of 230. I ran it at a fast idle for a few minutes and then turned off.

Used someone's idea of making a metal plate. That was a good idea. I think I could have used high temp TRV to seal the intake leakes and the metal plate would hold the broken part in place.

Only time will tell if JB holds.

Can't post the pic of the metal patch

George

Used someone's idea of making a metal plate. That was a good idea. I think I could have used high temp TRV to seal the intake leakes and the metal plate would hold the broken part in place.

Only time will tell if JB holds.

Can't post the pic of the metal patch

George