GermantownGreen

Well-known Member

- Location

- Montrose MO

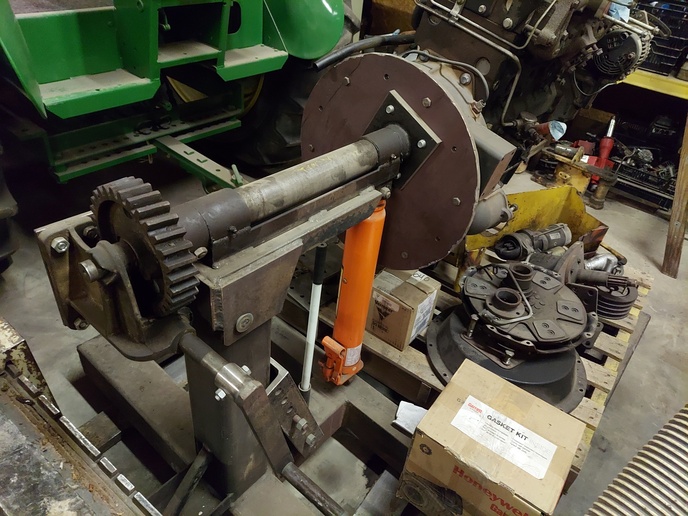

Any ideas out there if this is still remotely fixable or replaceable.

Belongs to cousin, put father in law's

354 Perkins on the stand, and the internal gear didn't like the weight.

Was fashioned to be able to take motor from horizontal to upside down.

Thanks for any help, GG,. Wes from west central Missouri.

Belongs to cousin, put father in law's

354 Perkins on the stand, and the internal gear didn't like the weight.

Was fashioned to be able to take motor from horizontal to upside down.

Thanks for any help, GG,. Wes from west central Missouri.