You should upgrade or use an alternative browser.

- Thread starter Rkh

- Start date

Janicholson

Well-known Member

Pressure switch adjust

Janicholson

Well-known Member

buickanddeere

Well-known Member

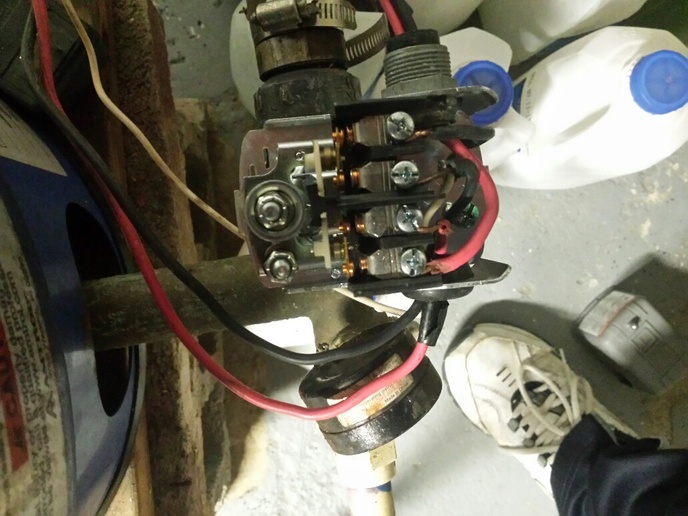

Actually one screw is pressure and the other screw is differential pressure .

MarkB_MI

Well-known Member

- Location

- Motown USA

That's what I remember.

showcrop

Well-known Member

The large nut adjusts both cut-in and cut-out at the same time. The small one adjust only the cut-out enabling you to narrow or broaden the range. So you back the big one out in order to get down to 30 then turn the little one in, in order to get the cut-out up to 50. I would go with a 25 lb. range

Russ from MN

Well-known Member

- Location

- Bemidji MN

guido

Well-known Member

Large spring is for adjusting the RANGE, cut in cut out. Loosen that nut a few turns and see what happens. The tank bladder pressure should be 2# ponds less then the cut in pressure.

You should have a 20 pound cut in and cut out differential. If your differential stays the same as now, you can then adjust the high pressure cut off with the small spring adjust nut,

Guido.

john in la

Well-known Member

The big nut adjust the cut off pressure.

Tightening it a quarter turn will raise the cut off and cut on pressure by 2 or 3 lbs.

The small nut adjust the difference between the cut on and cut off pressure.

I really do not recommend messing with this adjustment because it is hard to get the factory setting of 20 lbs.

If you have never messed with it your spring is most likely loosing tension.

Since we are talking less than $30 I would replace the whole switch with new.

showcrop

Well-known Member

(quoted from post at 10:30:22 12/05/21) Seems you got all kinds of answers.

The big nut adjust the cut off pressure.

Tightening it a quarter turn will raise the cut off and cut on pressure by 2 or 3 lbs.

The small nut adjust the difference between the cut on and cut off pressure.

I really do not recommend messing with this adjustment because it is hard to get the factory setting of 20 lbs.

If you have never messed with it your spring is most likely loosing tension.

Since we are talking less than $30 I would replace the whole switch with new.

John, from what I read here most answers are a little different but pretty much agreeing. I have adjusted many of these for customers. I have never found it hard to get it where I want it. These controls being usually just above basement floor level tend to get condensation and corrosion on them pretty quickly in my experience. This one is still shiny new so I wouldn't discard it, I would adjust it for my personal needs. They are adjustable for various reasons.

buickanddeere

Well-known Member

In order to reduce the number of stop start cycles. The pump system here is set for 25-60psi.

The differential small nut was backed off until there was barely any spring tension, then tightened two turns.

Adjusted the large nut to obtain a cutout pressure of 60psi.

Actually works well for watering the tree plantation etc. The spray pattern varies and provides better coverage.

buickanddeere

Well-known Member

showcrop

Well-known Member

(quoted from post at 11:42:16 12/06/21) Pump cycling on and off is a symptom of a waterlogged pressure tank. This means there is no air pocket above the water in the tank. There is a valve on the side of the tank that lets a little air in ever time the tank empties down below the water level when operating and lets a little air in. Also there is a bleed valve in the first pipe joint in the well that lets the water bleed down below the valve and when the pump starts this air is injected into the tank to create the air above the water. If it is a tank with a bladder then the bladder may be busted.

Hurley, the system that you describe is very outdated. I have seen one or two of those but not in the last 45 years. They have all been replaced with bladder tanks.

560Dennis

Well-known Member

- Location

- Madison,Ohio

Dont see one on that one.

showcrop

Well-known Member

(quoted from post at 07:25:43 12/09/21) I recommend square D one with low pressure cut off .

Dont see one on that one.

2X with low pressure cut-off.

Similar threads

- Replies

- 9

- Views

- 446

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy