Butch(OH)

Well-known Member

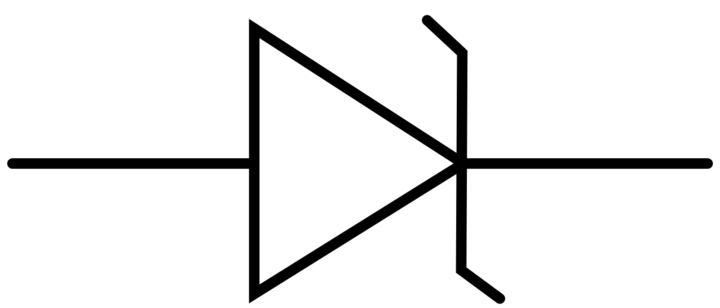

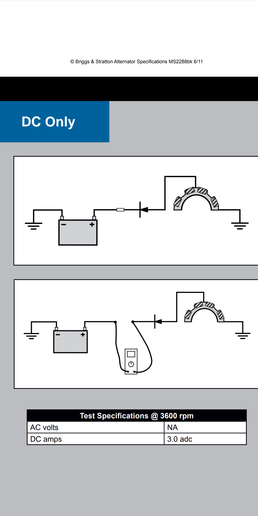

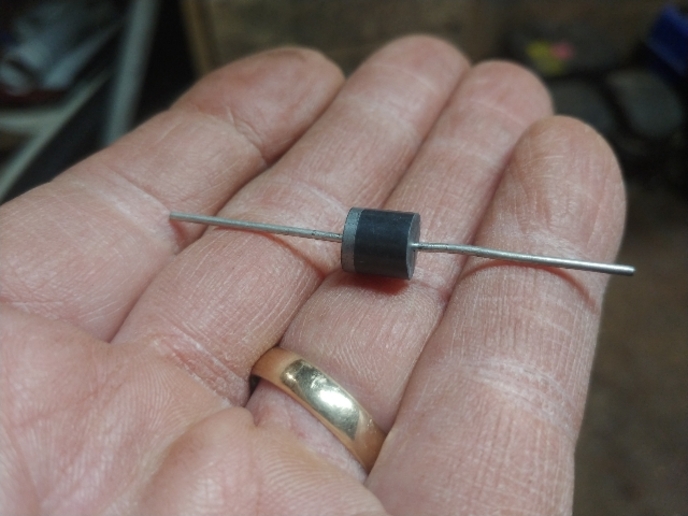

Sorry for the necessarily long question here but I am close to the lowest level when it come to modern electronic gizmos. I do manage to feel my way around old school charging and currently I have have two small engines in the shop that were not charging the batteries. These are not regulated two wire AC type but the old one wire sytem with a stator under the flywheel that produces 25 or so volts AC and a single wire with a diode in it going to the battery. The diode rectifies the AC currect and also cut voltage in half. Now on to my problems. Engine number 1 has a diode that reads shorted both directions. The B&S part is pretty spendy so I go online and find some diodes rated at 20 amps and like 1000 volts for a dollar each. I wired one in on engine 1,, yes it was installed the correct direction, yes the battery was new and charged. Start the engine up and check the voltage and it is just over 13 and coming up as it should with one of those 5? or less Amp systems. Fixed! but after 30 seconds it quit charging and the diode was so hot it burned my finger tip and when I shut the engine down it was shorted both directions. OK junk diode,, soldered in another and it did the same thing,, ok I bought junk diodes. Next try, it so happens that I keep several type 5010 bridge rectifiers in the shop because my ST type stand by generator uses them. They are rated at 50 amps. I just used the + and minus terminals and again it was installed the correct direction. As I understand a bridge rectifier I am using half the diodes in parallel, or half current each?? Well after a couple minutes running and charging correctly that bridge rectifier started smoking and it too is now shorted both directions. OK enough of that engine for now and I proceeded into engine number 2 which is powering an 8 KW gen set and has same problem which is battery not charging and wire that is supposed to charge the battery is producing 29 volts AC. Bad diode as I was taught in school. I get behind the panel and find that they used the same 5010 bridge rectifier only using the + and - terminals just like I tried on engine #1. It is obvious that it was that way from the factory and not a bodge by a previous owner. The rectifier was shorted both ways as I suspected so I wired in one of my spare 5010s and it charged for 15 minutes, got hot and same deal as before is now shorted both ways.

I am thinking there are other issues beside bad diodes. I hate to buy a $30 BS diode and have it do the same thing, they are tiny and shurly wont handle the current that my replacements will? Anyone care to take a stab at what's going on?? Appreciate it.

I am thinking there are other issues beside bad diodes. I hate to buy a $30 BS diode and have it do the same thing, they are tiny and shurly wont handle the current that my replacements will? Anyone care to take a stab at what's going on?? Appreciate it.