Steve@Advance

Well-known Member

I've got an old British built OD grinder in the shop.

It has a counter weight that hangs on a 1/8" cable that keeps the slack pulled out of the wheel head lead screw. My guess is the weight probably weighs 150#.

The cable pulled out of the ball that was soldered on the end. I'm replacing the cable and can make a new ball. Probably a sleeve will be easier, doesn't matter, just needs something on the end to hold it.

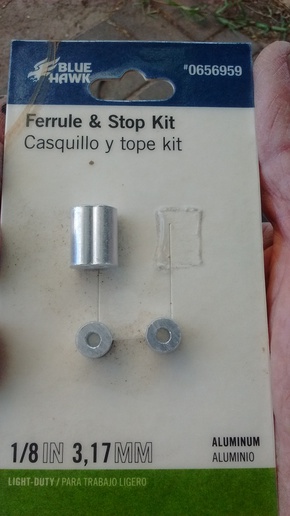

Any suggestions for attaching the sleeve? Will plumbing solder and flux paste work? Or crimp it in the press? Or both? Brass or steel?

Or should I try to find a factory crimped cable? Any sources that are interested in a one time sale?

I don't want to take any chances of it failing, a real bear to get to!

Thanks!

It has a counter weight that hangs on a 1/8" cable that keeps the slack pulled out of the wheel head lead screw. My guess is the weight probably weighs 150#.

The cable pulled out of the ball that was soldered on the end. I'm replacing the cable and can make a new ball. Probably a sleeve will be easier, doesn't matter, just needs something on the end to hold it.

Any suggestions for attaching the sleeve? Will plumbing solder and flux paste work? Or crimp it in the press? Or both? Brass or steel?

Or should I try to find a factory crimped cable? Any sources that are interested in a one time sale?

I don't want to take any chances of it failing, a real bear to get to!

Thanks!