Stephen Newell

Well-known Member

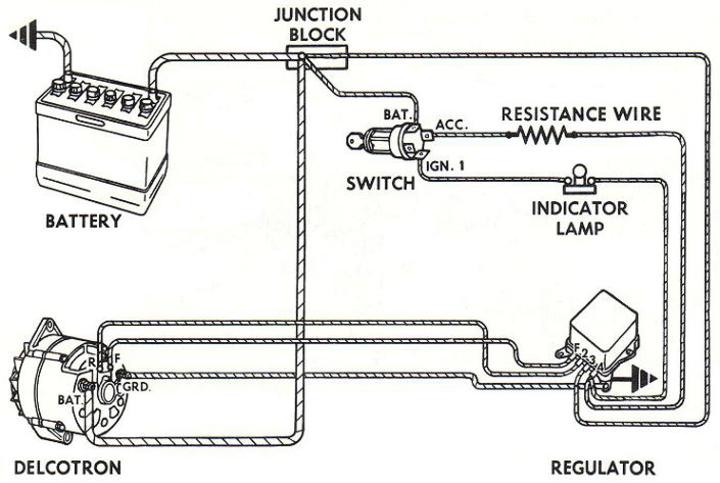

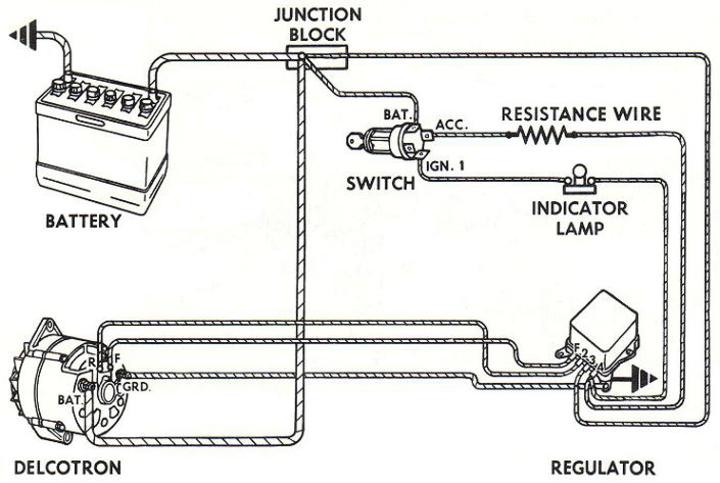

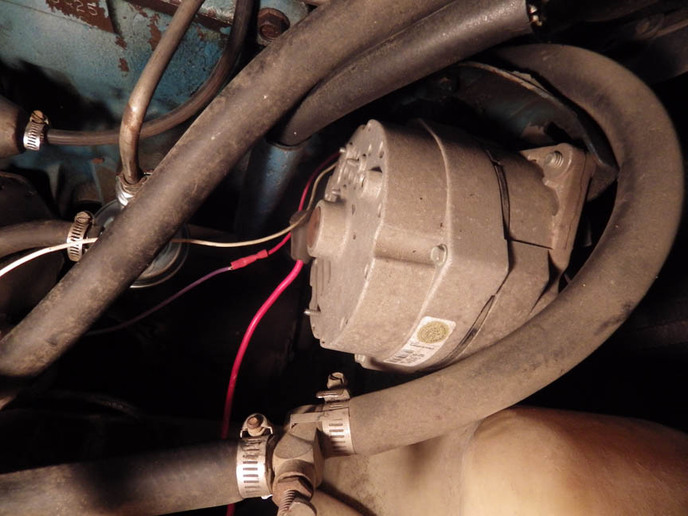

I'm trying to install a voltage regulator to my 1975 jeep cj5 where it's never had one. I went to NAPA and bought a VR142SB voltage regulator which is suppose to be just a universal external regulator. Of course the thing didn't have any instructions with it so I found some basic instructions online which I'm going by. Where I'm having trouble is the line which calls for a resistance wire. I went to two different auto parts stores this evening and nobody has any idea what resistance wire is, me included. Anyway since the jeep has a coil resister between the power and the coil is the resistance wire necessary? If so can someone recommend a suitable wire for this purpose. It looks like I may have to mail order the wire.