Brad Buchanan

Member

Hey everyone!

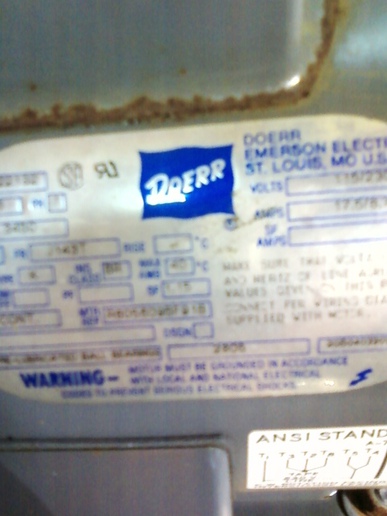

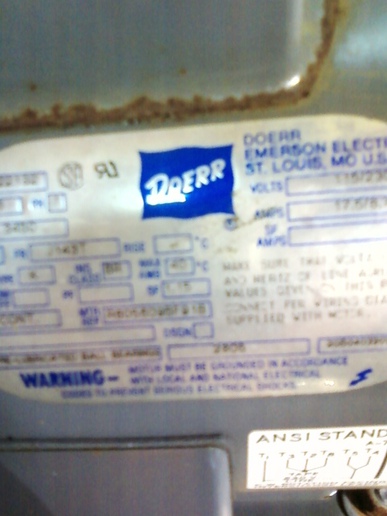

I have been wanting a good jointer for a long while and after bidding on several ones I finally won this one in a GSA auction.

So the wife and I piled into the Guppie, her brand new Ford Focus and headed for Harrisburg PA.

I brought enough tools to take the critter apart (I thought).

We arrived and I found that the major parts of the machine were put together with allen head cap screws and I never thought to bring those sockets.

So, after much sweating, tugging and pinched fingers I was able to fit the machine into the rear of the car with some help from a couple of fellows from the depot (who were great) and we were on our way.

Unloading was a breeze with a forklift (thanks Glennster) and I started cleaning the rust off. It is missing the fence and some of the accessory points are broken off the castings but the tables cleaned up nice.

So for $99.00 did I get a deal or am I just spinnin' my wheels?

As usual all comments are welcome, pro or con.

Thanks, Brad

I have been wanting a good jointer for a long while and after bidding on several ones I finally won this one in a GSA auction.

So the wife and I piled into the Guppie, her brand new Ford Focus and headed for Harrisburg PA.

I brought enough tools to take the critter apart (I thought).

We arrived and I found that the major parts of the machine were put together with allen head cap screws and I never thought to bring those sockets.

So, after much sweating, tugging and pinched fingers I was able to fit the machine into the rear of the car with some help from a couple of fellows from the depot (who were great) and we were on our way.

Unloading was a breeze with a forklift (thanks Glennster) and I started cleaning the rust off. It is missing the fence and some of the accessory points are broken off the castings but the tables cleaned up nice.

So for $99.00 did I get a deal or am I just spinnin' my wheels?

As usual all comments are welcome, pro or con.

Thanks, Brad