rlp in Co.

Well-known Member

Well, I'm very disappointed today. I got the welder wired up and tried it out, but it won't hold an arc, even at 225 amps. I was using 7018 1/8 inch Forney rod.

I also tried some 3/32 7018 AC rod that I couldn't get to work very good on AC, and it welded that good, on DC.

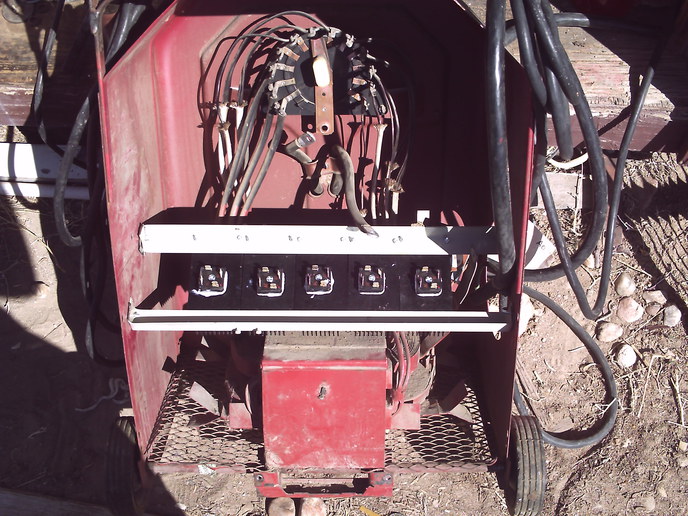

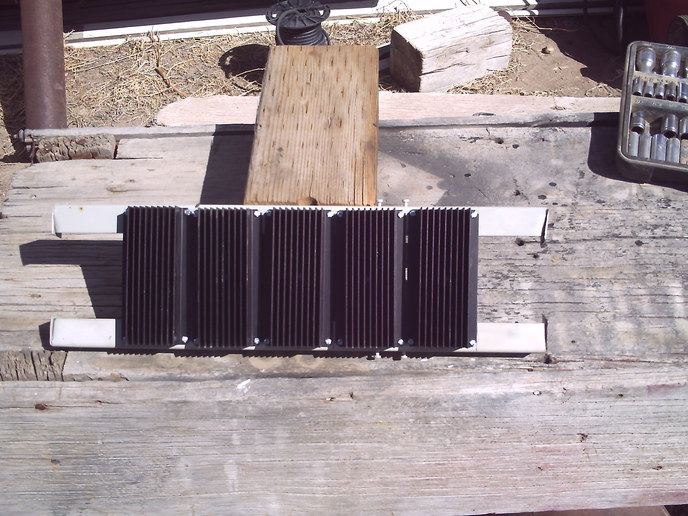

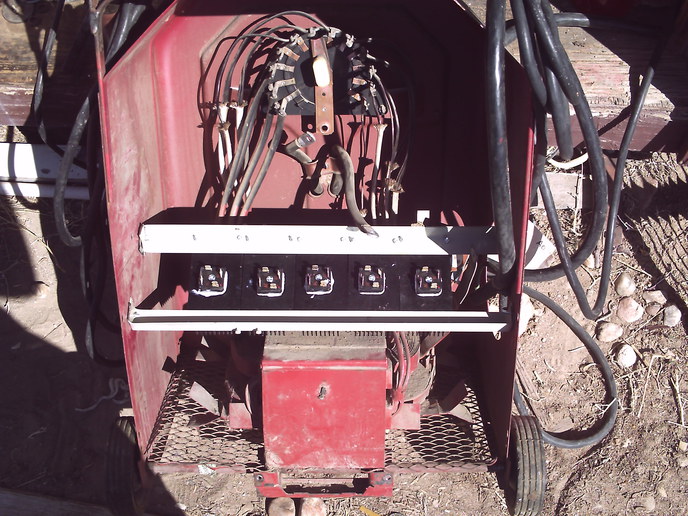

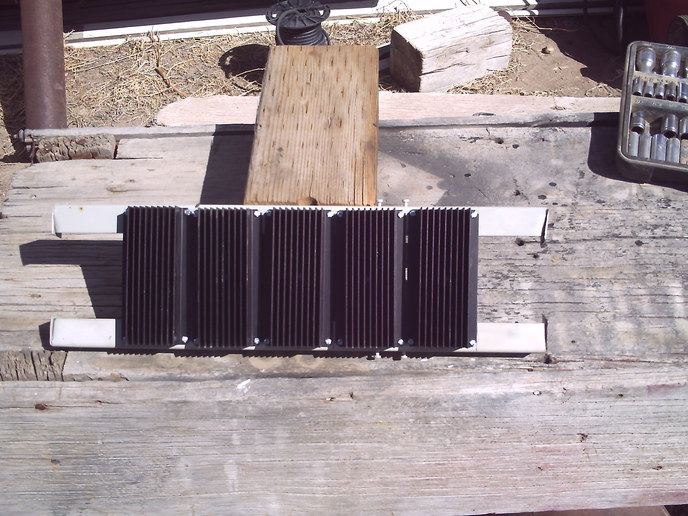

I double checked the voltage polarity, and it is positive DC on the ground wire. So, I'm guessing that I have to add some filtering to smooth the pulsating DC to pure DC. What kind of filter do they use? Maybe someone has a picture of what is inside of a DC welder.

I also tried some 3/32 7018 AC rod that I couldn't get to work very good on AC, and it welded that good, on DC.

I double checked the voltage polarity, and it is positive DC on the ground wire. So, I'm guessing that I have to add some filtering to smooth the pulsating DC to pure DC. What kind of filter do they use? Maybe someone has a picture of what is inside of a DC welder.