So I rebuilt a b275 diesel, engine bd144 it fired right up & ran great until I noticed the head gasket leaking (bubbles) I decided to take the head back off & do it right. I ordered a new head gasket kit & it came with 2 rubber o-rings. In another group an englishman told me my gasket was leaking bc I forgot the o-rings & told me in the UK they are all sold with o-rings. The kit I bought first had none. Does anyone know where the proper placement of these o-rings is?

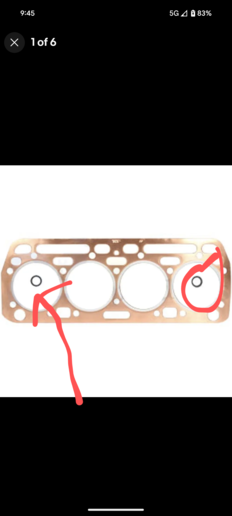

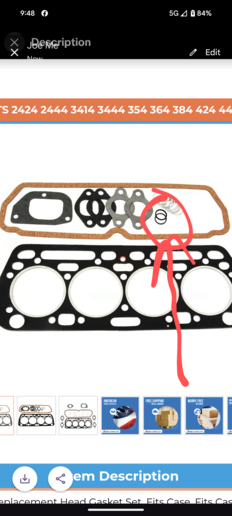

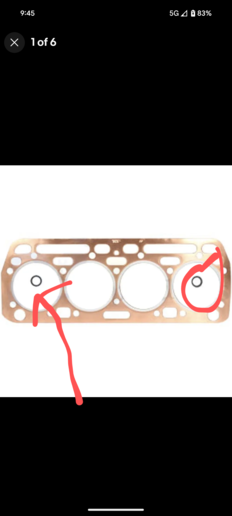

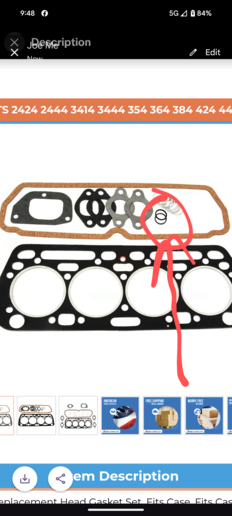

I also added 2 photos from the englishman showing me where the o-rings go, problem is on one side of the block there is no water jacket there. I have 2 new gaskets, One does not even have a hole in that area (bottom left corner) should I put the 2 o-rings around the round water jackets? Can anyone help me with this so I get it right this time?

I also added 2 photos from the englishman showing me where the o-rings go, problem is on one side of the block there is no water jacket there. I have 2 new gaskets, One does not even have a hole in that area (bottom left corner) should I put the 2 o-rings around the round water jackets? Can anyone help me with this so I get it right this time?