You should upgrade or use an alternative browser.

- Thread starter Shortrun

- Start date

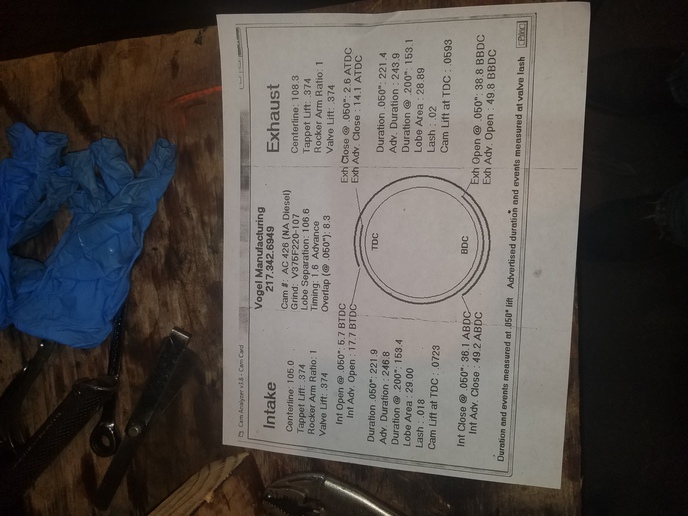

The stock ones I ve measured had no overlap at .050" the Ford 456 cam had around 16 degrees of gap. The 466 Deere had around 24 degrees of gap at .050".

My old ford manual indicates 17 degrees of overlap, but has not specs on lift.

My performance cams have around 12 degrees of overlap at .050" thousandths.

Good information.

I think that 0.050 is measured at the valve stem. And the degrees are crankshaft degrees and not camshaft. Is that correct?

Also i have seen just about all the cams i can find info on (cars motors) are about 55% on the before TDC and 45% after TDC. So for example intake

opens at 15 degrees BTDC and exhaust closes at 10 ATDC. Is this the normal?

I appreciate the help.

Intake center line falls in around 99 to 107 on most everything I ve measured and setup.

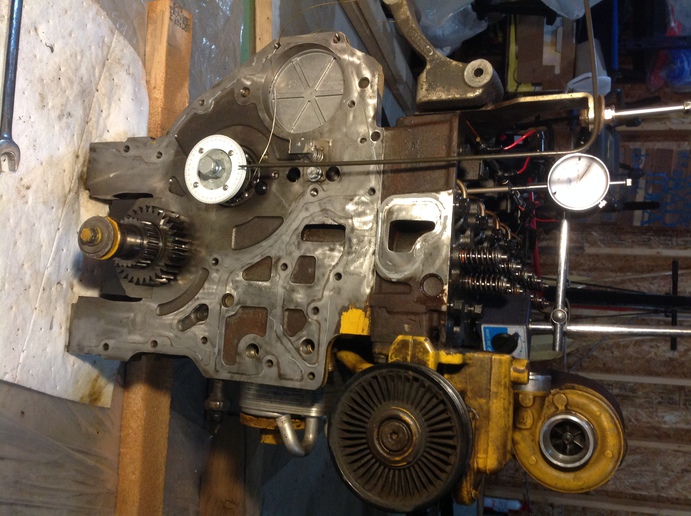

What are you doing with that hideous engine? That thing looks like a bear to work on.

Some cam numbers:

Deere 466 @ .050"

Intake opens 12 B TDC

Intake closes 22 A BDC

Exhaust opens 13 A TDC

Exhaust closes 16 B BDC

Ford 456 @ .050"

Intake opens 7 B TDC

Intake closes 20 A BDC

Exhaust opens 10 A TDC

Exhaust closes 27 B BDC

Ford 5000 from ford service manual, no spec on lift.

Intake opens 10 B TDC

Intake closes 34 A BDC

Exhaust opens 37 B TDC

Exhaust closes 7 A BDC

The trouble with the engine shortrun is working on is it has no timing marks or key on the cam. The injection pump lobs are on the cam as well with unit pumps for each cylinder. The timing procedure involves special tools to lock the cam at a certain timing position.

Shortrun, if you could determine port closure on the #1 pump in relation to the intake centerline for the same cylinder then you could set the injection pump timing at say 14ish degrees BTDC and see where the intake centerline falls and see if it makes sense. The pump timing will have far more effect on how that engine runs than the other events.

Since i know so little about diesels i dont know if this is possible. On an engine that is all apart like mine is now. Can i supply fuel to the injector pump

at about 60 psi. Then slowly turn the camshaft by hand. A wait for the spray of fuel coming out the (now removed) glow plug hole? I really have no

clue.

But if i can this would be better than using the valve locations to time the cam.

I dont know what "intake center line" is?

60 psi won t open an injector, they pop open above 3,000 psi usually.

But 60 psi supplied to the pumps with the injector line disconnected should indicate when the pump begins it s injection event. This is known as the spill port method. You can do a search about it, lots of information and videos on it. Depending on the delivery valve spring in the unit it may or may not flow fuel with 60 psi applied, also, make sure the fuel rack is set to run when you try this. It should get you heading further in the right direction.

I will reasearch spill port. I had actaully read that but did not understand. I do now, so i will check if this will work for me.

If it does this will be more accuate timing for my camshaft.

I read many engine inject close to 14 BTDC, as you mentioned. Is that a number i can assume is right (close) or are there some

John Deere that are far from that?

I guess the range is 10 to 20 degrees BTDC, outside of that the engine will not run.

In the end the motor starts an runs pretty good. I used all the information i got here, and really appreciate those who took time to help me.

I ended up watching the intake and exhaust valves overlap. Then took the center point of those 2 positions. Next i took that cam center point and placed it about 3 deegrees before top dead center on the crankshaft. ( i wanted to be sure i was advaned and not retarded) locked the cam shaft gear to the camshaft. (Just tightened the big bolt holding the two)

I didnt have any problems getting some oil pressure. Also no problems bleeding the fuel / injectors.

buickanddeere

Well-known Member

Unless valve reliefs are cut into the pistons at the expense of compression.

Similar threads

- Replies

- 23

- Views

- 996

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy