So I got the finish mower hooked up, it's sitting too low in the front and it looks like you can't adjust things with the hydraulics, it's "all or nothing". I think someone here advised me the top link will lift/lower the front, do I lift it shortening or tightening it? Reason I ask is the guy I got the mower from gave me a top link with one end bent, not sure how much adjustment I'm going to get out of it. Hope this doesn't ruin my plans...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter hogluvr

- Start date

Lynn Patrick

Well-known Member

The top link should be adjusted to allow the mower to float. the best way to set the front height is a set of limiter chains that hook from the top link pin on the tractor down to the pins on the mower. I tried to find a pic of them but couldn't right now. Maybe someone has a pic to share???

(quoted from post at 17:59:44 07/30/21) I would go buy a top link. No sense making things harder.

Jerry

Yeah I totally firgot about it and was just trying to get my first cut in, I'm assuming now that's what adjusts the front of the mower?

Jim.ME

Well-known Member

- Location

- central ME

Your PTO shaft appears too long. There should be some area available for it to slide. It will need to get shorter as the cutter is lifted.

deanostoybox

Member

<a href=https://www.yesterdaystractors.com/MHSK1_Mower-Deck-Height-Stabilizer-Kit_9603.htm>limiter chains</a>

shaun wallace

Well-known Member

The tractor end is different series ujoint than gear box and is out of phaze. Getting same series ujoint for tractor would gain couple inch in travel.

deanostoybox

Member

+1 on the wheel kit

So there are a couple of things to consider here which some of the others have already said.

1. Setting the front of the mower. As was eluded to you need either limiting chains or caster wheels in the front of the mower to set the height of the mower. You want the front about 1/4-1/2" lower than the rear of the mower. Chains would be easiest.

2. The top link. You must have a top link on it but you can't have a fixed toplink here. You'll bend stuff up (note the condition of your previous link and the attachment point on the tractor). If the toplink connects to a hardpoint on the mower and that point doesn't swivel I suggest using a chain vs a top link. You have to make sure the machine has the ability to tip forward and backward a few inches in relation to the tractor. Let the casters/limiting chains set your front height not the top link. If something binds up you're gonna bend stuff.

3. See if you can rotate your PTO shaft 90 degrees. You're out of phase and it's really gonna shake the crap out of you and the machine.

4. It appears right now that you're PTO shaft is too long. You DO NOT WANT THE PTO TO EVER BOTTOM OUT ON THE TRACTOR. You'll break internal parts. At it's shortest you want to be able to remove the PTO from the tractor. You might have an issue with the PTO shaft pulling out on the mower because of this. I'll get into this on a following post.

5. For the love of god PLEASE put a shield on the PTO. I realize that all of us have absolutely no intentions of getting caught up in one, but ultimately it happens and there are a few universal facts about this and those are.

a. The tractor doesn't care how much your family and kids love you.

b. It doesn't care how loud you scream for help.

This post was edited by kossuth on 07/31/2021 at 01:16 am.

1. Setting the front of the mower. As was eluded to you need either limiting chains or caster wheels in the front of the mower to set the height of the mower. You want the front about 1/4-1/2" lower than the rear of the mower. Chains would be easiest.

2. The top link. You must have a top link on it but you can't have a fixed toplink here. You'll bend stuff up (note the condition of your previous link and the attachment point on the tractor). If the toplink connects to a hardpoint on the mower and that point doesn't swivel I suggest using a chain vs a top link. You have to make sure the machine has the ability to tip forward and backward a few inches in relation to the tractor. Let the casters/limiting chains set your front height not the top link. If something binds up you're gonna bend stuff.

3. See if you can rotate your PTO shaft 90 degrees. You're out of phase and it's really gonna shake the crap out of you and the machine.

4. It appears right now that you're PTO shaft is too long. You DO NOT WANT THE PTO TO EVER BOTTOM OUT ON THE TRACTOR. You'll break internal parts. At it's shortest you want to be able to remove the PTO from the tractor. You might have an issue with the PTO shaft pulling out on the mower because of this. I'll get into this on a following post.

5. For the love of god PLEASE put a shield on the PTO. I realize that all of us have absolutely no intentions of getting caught up in one, but ultimately it happens and there are a few universal facts about this and those are.

a. The tractor doesn't care how much your family and kids love you.

b. It doesn't care how loud you scream for help.

This post was edited by kossuth on 07/31/2021 at 01:16 am.

Some additional thoughts I wanted to share given it's 4:30 am and for whatever reason I can't sleep. Recently I put my granddad's little 8n back into action up at my mom and dad's place to do some mowing around the property (7 acres). I procured a Woods RM600 finish mower so it's not that dissimilar to yours in setup. On the Woods mower the gearbox is way forward on the mowing machine similar to your setup. What I found with a traditional overrunning clutch is that the PTO shaft was super short and would easily come out when you lifted the mower even alittle. Not much I could do about this except somehow make the shaft longer. How I did that was I built an entirely new shaft that had the overrunning clutch built in. Weasler (maybe other vendors also) make PTO components and in their catalog you can find a ton of different items. So rather than having to deal with the 8" long overrunning clutch hanging off the back messing with angles because of the length etc I lost only about 1.5" or so due to the slightly longer yolk with the clutch integrated.

This was not a cheap option at close to $300 but it's the only one that made any sense in my situation TBH.

Here is the PTO coupler I used on the tractor (granddads has a 1 3/8 shaft) https://www.weasler.com/product/ab2aw20-series-overrunning-clutch-quick-disconnect-yoke-2/

This post was edited by kossuth on 07/31/2021 at 01:39 am.

This was not a cheap option at close to $300 but it's the only one that made any sense in my situation TBH.

Here is the PTO coupler I used on the tractor (granddads has a 1 3/8 shaft) https://www.weasler.com/product/ab2aw20-series-overrunning-clutch-quick-disconnect-yoke-2/

This post was edited by kossuth on 07/31/2021 at 01:39 am.

(quoted from post at 19:12:52 07/30/21) The tractor end is different series ujoint than gear box and is out of phaze. Getting same series ujoint for tractor would gain couple inch in travel.

Not sure what you mean by different series? But yeah, I agree it's too long.

(quoted from post at 01:37:46 07/31/21) Some additional thoughts I wanted to share given it's 4:30 am and for whatever reason I can't sleep. Recently I put my granddad's little 8n back into action up at my mom and dad's place to do some mowing around the property (7 acres). I procured a Woods RM600 finish mower so it's not that dissimilar to yours in setup. On the Woods mower the gearbox is way forward on the mowing machine similar to your setup. What I found with a traditional overrunning clutch is that the PTO shaft was super short and would easily come out when you lifted the mower even alittle. Not much I could do about this except somehow make the shaft longer. How I did that was I built an entirely new shaft that had the overrunning clutch built in. Weasler (maybe other vendors also) make PTO components and in their catalog you can find a ton of different items. So rather than having to deal with the 8" long overrunning clutch hanging off the back messing with angles because of the length etc I lost only about 1.5" or so due to the slightly longer yolk with the clutch integrated.

This was not a cheap option at close to $300 but it's the only one that made any sense in my situation TBH.

Here is the PTO coupler I used on the tractor (granddads has a 1 3/8 shaft) https://www.weasler.com/product/ab2aw20-series-overrunning-clutch-quick-disconnect-yoke-2/

This post was edited by kossuth on 07/31/2021 at 01:39 am.

Thanks for all the info! And yeah I'm up early for a Saturday, damned dogs! 😁

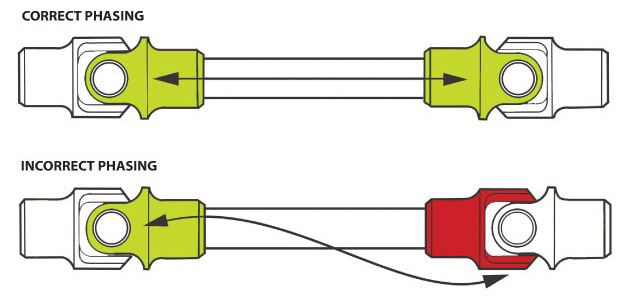

hat he meant was phase. Your phasing is 90 degrees out. The series of u-joint has nothing to do with it. Its actually very common in the automotive world where you might have one style of yolk on a driveshaft on one end and another type on the other. As long as they are in phase all is good. If its a square cut shaft you should be able to just pull it and rotate it 90 degrees and be good. If its something else then you would need to make or have a new shaft made. Below is what your phasing should be.(quoted from post at 10:29:37 07/31/21) I've got what is probably a dumb question. Could I just cut that driveshaft down to make to make it line up better and get some slack? If not where can I get the correct one, I didn't understand the post about it being a different series?

A short YouTube video on why phasing is important. The angles are as well. With that said when you have the mower setup right the angles of the mower will match the PTO on the tractor. The phasing those will screw stuff up regardless of angles.

https://youtu.be/Idk3BVDVHq4

https://youtu.be/Idk3BVDVHq4

Jim.ME

Well-known Member

- Location

- central ME

Phasing aside as it appears info has been posted for you on that.

The series is related to the size of the u-joints and yokes. There are different sizes and styles. In your picture it appears the yokes are different on each end of your shaft as the lock styles are different. You would need to measure the joints them selves to see if they are the same.

Here is some info that may help you:

https://www.paulbparts.com/wp-content/uploads/2016/02/determining-your-pto-series.pdf

Thank you guys for all the excellent info! After going through it I have to agree that the pic I posted showed 2 different series joints and the 2 halves were out of phase.

If you've followed any of my other posts it was suggested that an ORC was unnecessary with a finish mower so I removed it hoping to free up some space for the driveshaft and discovered it was also an adapter, my PTO is 1-1/8" so now I have another issue as well.

So what are my solutions? I would get an adapter to convert 1-1/8" to 1-3/8", but I've heard they don't hold up, and then I'm still dealing with the different series u-joints. I can swap out the 1-1/8" PTO shaft for a 1-3/8" PTO shaft but I will still have the different u-joints + a questionable overseas PTO shaft. I can get a different end yoke to fit the 1-1/8" PTO but again the different series ends. Are they a big deal? Does anyone have any further input or suggestions? Am I looking at this correctly?

carlntexas

Member

I had the same problem on my finish mower drive shaft was too long. I cut a few inches of and used the orc don't know about the phase thing.

Jim.ME

Well-known Member

- Location

- central ME

PTO shaft on the tractor is one issue. Changing it to the standard 1-3/8" shaft will mean it will be ready to accept common PTO shafts you will encounter if you want to use other implements.

Changing the tractor end yoke on the mower driveline to 1-1/8" to match the tractor will lock using the mower to that tractor or another with the 1-1/8" PTO shaft.

Ideally all joints and yokes should be the same series, but I would worry more about getting the phasing correct. If you have a bad u-joint or yoke that needs replacing, then match the series of the joint and yokes on the other end of shaft.

Just my thoughts, others will vary.

Smokeonthewater

Member

Change the shaft, get the driveshaft in phase, and mow

Jim.ME

Well-known Member

- Location

- central ME

(quoted from post at 15:33:12 08/03/21)

If I did that would the two different series u-joints and yokes on each end of the driveshaft be a concern?

It can have two different size u-joints. The size of the u-joint determines the series, so the shaft would be considered to only have the rating of the smaller of the two joints. It will run ok, if it is in phase. So don't worry about that until you have a bad joint or yoke.

OK, with that being said is the consensus that I'd be better off replacing the PTO shaft with one that is 1-3/8" vs using an adapter and keeping the ORC to use with any other implements vs getting a yoke with 1-3/8" splines and keeping the ORC for other things? Just trying to get the best-case scenario. And sorry for all the questions!

Smokeonthewater

Member

To get your shaft in phase, just pull it apart, turn 90* and put it back together

Once you change the shaft your current orc will be useless to you...

The only implement you would need an orc for is a brush hog and you would need a new orc to fit your new shaft

Once you change the shaft your current orc will be useless to you...

The only implement you would need an orc for is a brush hog and you would need a new orc to fit your new shaft

(quoted from post at 08:44:13 08/03/21) Change the shaft, get the driveshaft in phase, and mow

Do these aftermarket driveshafts hold up? Probably made overseas

Similar threads

- Replies

- 62

- Views

- 4K

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy