grandpa Love

Well-known Member

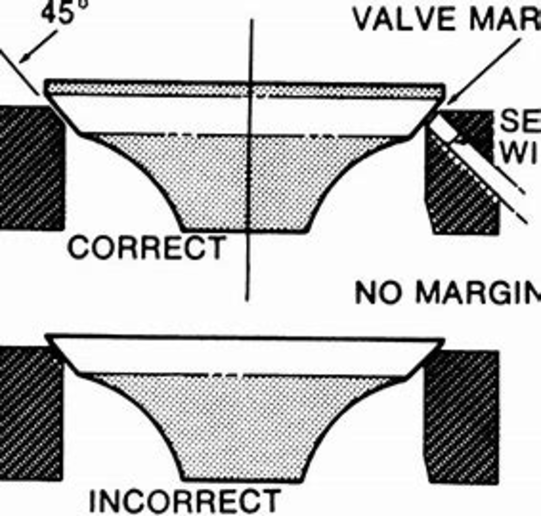

'47 8n. One busted valve guide. Pulled

all the valves out and cleaned everything

real good. Put all the exhaust valves

back in and checked them. .016 on three,

.025 on one. One keeper is loose,

thinking a weak spring, will try a

different spring. Got one intake valve

assembly coming, plan to pop it in there

and hope it fixes the problem. Assembly

came out of an old tractor, it's not new.

Any issues? Tractor may get rake duty or

finish mower. Not hard use. Enjoying

digging into a different project, my wife

is loving it too. Be rewarding to see it

run!

all the valves out and cleaned everything

real good. Put all the exhaust valves

back in and checked them. .016 on three,

.025 on one. One keeper is loose,

thinking a weak spring, will try a

different spring. Got one intake valve

assembly coming, plan to pop it in there

and hope it fixes the problem. Assembly

came out of an old tractor, it's not new.

Any issues? Tractor may get rake duty or

finish mower. Not hard use. Enjoying

digging into a different project, my wife

is loving it too. Be rewarding to see it

run!