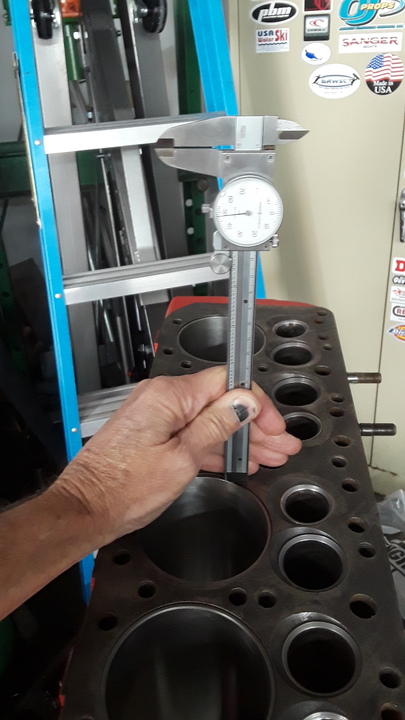

I am rebuilding my 8N engine block and my machine shop installed TISCO .040 sleeves into the block. The sleeves are recessed into the block

by .035 inch on three and one at .048. I measured the flange lip and its .040 thick. The old sleeves flanges are .052. I think they were

flush with the top of the block before I removed them. They must have not been seated in the counterbore because the counterbore is about

.085. I am concerned that the sleeve will move in the block an cause major damage to the engine. What are my options? Bore the block to fit

090 sleeves? Leave it as is?

I have check with other suppliers of the sleeves and all of the .040 sleeve have only .040 thick flanges. The .090 sleeves have a .061 thick

flange. If I bore out for .090 sleeves will the flange diameter go into the valve seat area?

Lot's of questions but no solutions yet. I need your help!

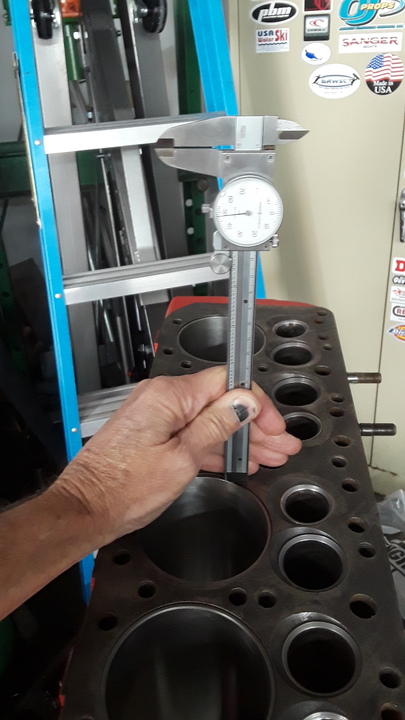

by .035 inch on three and one at .048. I measured the flange lip and its .040 thick. The old sleeves flanges are .052. I think they were

flush with the top of the block before I removed them. They must have not been seated in the counterbore because the counterbore is about

.085. I am concerned that the sleeve will move in the block an cause major damage to the engine. What are my options? Bore the block to fit

090 sleeves? Leave it as is?

I have check with other suppliers of the sleeves and all of the .040 sleeve have only .040 thick flanges. The .090 sleeves have a .061 thick

flange. If I bore out for .090 sleeves will the flange diameter go into the valve seat area?

Lot's of questions but no solutions yet. I need your help!