Hey everyone need a little help troubleshooting and ORC. The holes on the clutch will not match up flush with my PTO shaft. I replaced the seal and gasket for the PTO because it was leaking and put it back

in and tried the ORC and it is about 1/8 of an inch or less from lining up. It is a brand new ORC and I never tried putting it on before changing the PTO seal. Is there a possibility I didn't replace the seal

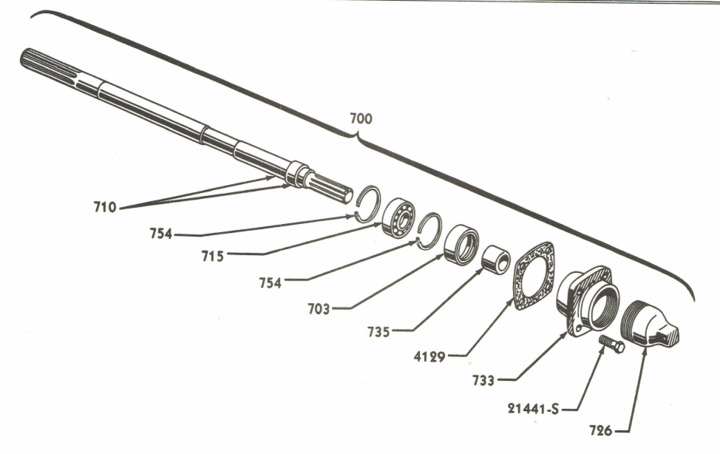

correctly? I attached the diagram from the manual and I put every piece in just like that. Maybe I didn't hammer something in all the way or maybe the clutch itself is bad? I ground down the outer bevel

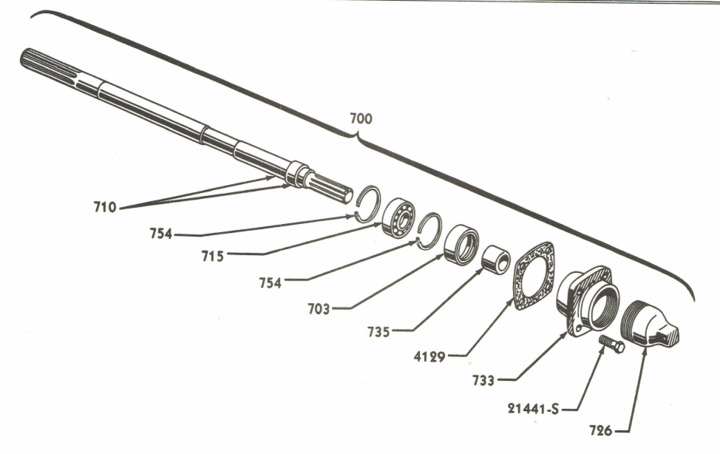

some and it didn't help. I also grinded the very edge of the fat end a little but I am afraid to go too far because the retaining clip in the ORC is right at the edge there (pictured).

Any ideas should I just keep grinding or remove the PTO shaft again? Maybe try a different one ORC?

in and tried the ORC and it is about 1/8 of an inch or less from lining up. It is a brand new ORC and I never tried putting it on before changing the PTO seal. Is there a possibility I didn't replace the seal

correctly? I attached the diagram from the manual and I put every piece in just like that. Maybe I didn't hammer something in all the way or maybe the clutch itself is bad? I ground down the outer bevel

some and it didn't help. I also grinded the very edge of the fat end a little but I am afraid to go too far because the retaining clip in the ORC is right at the edge there (pictured).

Any ideas should I just keep grinding or remove the PTO shaft again? Maybe try a different one ORC?