I am still looking for anyone who has tried the Vane type Hydraulic Pump Kit for Ford NAA that I have coming from Yesterday's Tractor. Any problems with changing it? Did it work good? I had previously posted the following under Ford instead of 8N,9N,2N:

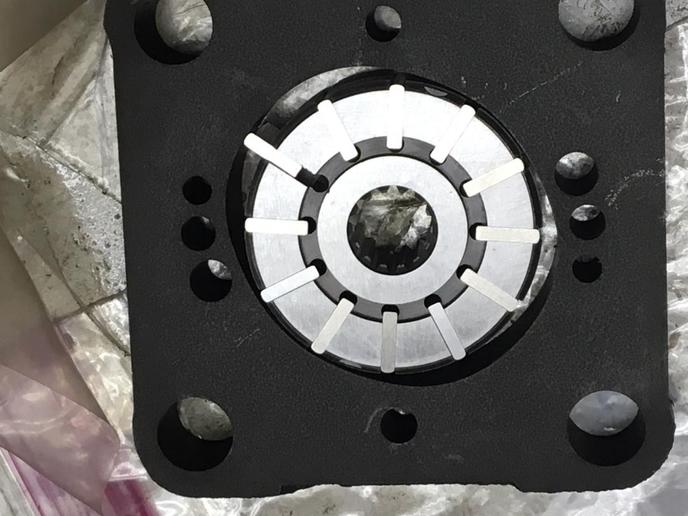

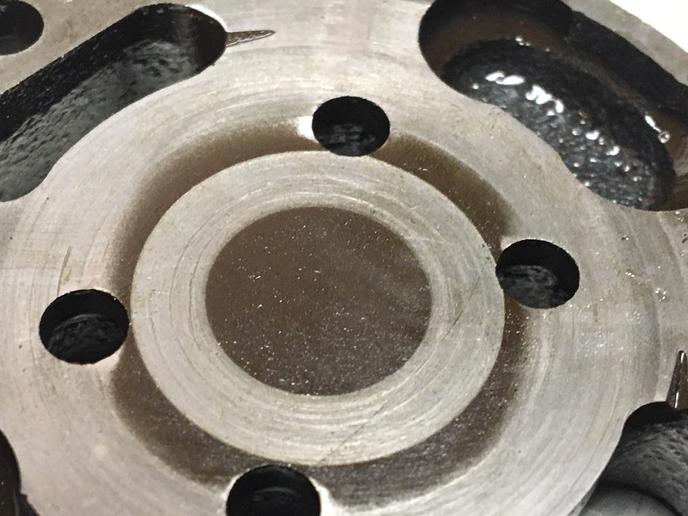

"I have done the testing to confirm that the pump is too wore out to produce enough pressure and just ordered the 5/8 Thick Vane Type Hydraulic Pump Kit from Yesterday's Tractor. Does anyone have experience with this kit? I see it comes with the body/rotor/vanes along with 2 O-rings. I am not sure how much I will need to take apart when I receive the kit and am wondering if I might be needing the seal and any gaskets that show up on the exploded parts view I found online. The pump does not leak now. I can still do some snow plowing (blade on front with cable going back to hydraulic arms) and do not want to take the pump apart until the kit arrives. I can plow for 15-20 minutes at a time before it stops lifting the bade. Any advice regarding installing the kit would be appreciated."

Thank you,

Steve

"I have done the testing to confirm that the pump is too wore out to produce enough pressure and just ordered the 5/8 Thick Vane Type Hydraulic Pump Kit from Yesterday's Tractor. Does anyone have experience with this kit? I see it comes with the body/rotor/vanes along with 2 O-rings. I am not sure how much I will need to take apart when I receive the kit and am wondering if I might be needing the seal and any gaskets that show up on the exploded parts view I found online. The pump does not leak now. I can still do some snow plowing (blade on front with cable going back to hydraulic arms) and do not want to take the pump apart until the kit arrives. I can plow for 15-20 minutes at a time before it stops lifting the bade. Any advice regarding installing the kit would be appreciated."

Thank you,

Steve