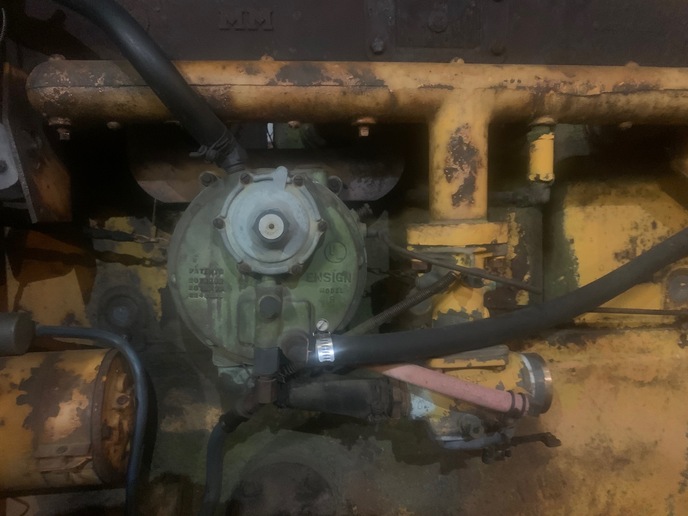

Looking for some guidance.. I acquired a 6 cylinder moline power unit, 605 cubic inch engine. It’s LP, I have spark but it does not fire off. I think I have an LP issue. A friend on my suggested that I change out the complete vaporizer and the carburetor. Again, I don’t hav a lot of experience with LP engines and I am only planning on mounting it to a agon running gear and taking it to our sho f display purposes but I want it to start good and operate.

Any ideas who or where I should call to get the proper vaporizer and if I need it the carburoator.

Thanks. And Merry Christmas

Any ideas who or where I should call to get the proper vaporizer and if I need it the carburoator.

Thanks. And Merry Christmas