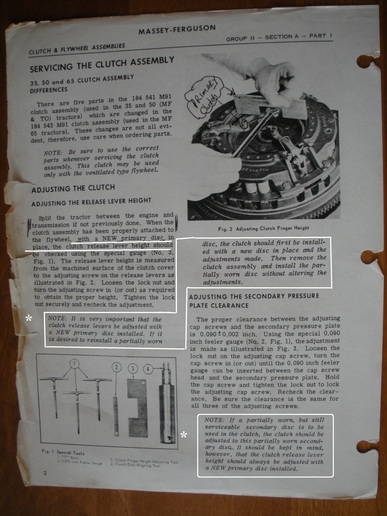

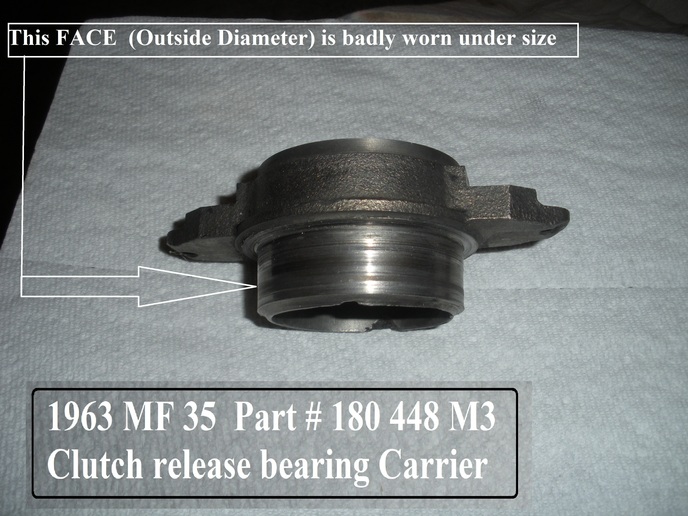

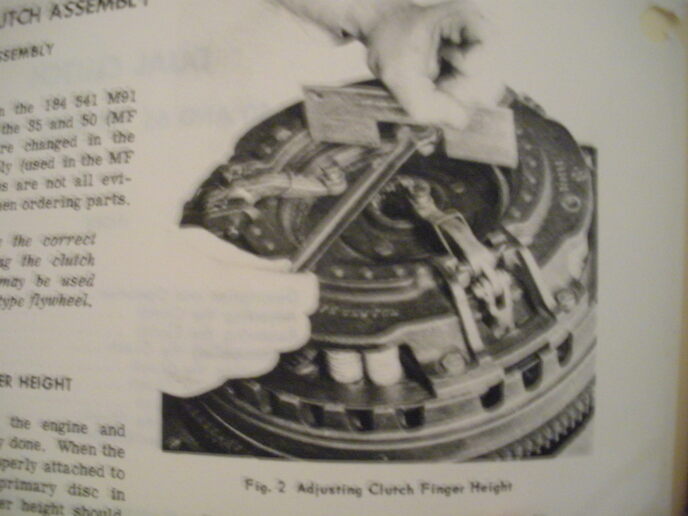

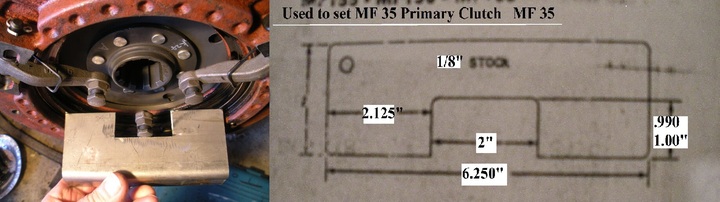

As the subject says I have a Massey Ferguson 65 and I can't get the PTO clutch to disengage. Adjusted the pedal linkage and free play per manual, then took the inspection cover off and adjusted the screws on the clutch... brought the clearance all the way down to .060 based on what I'd read online but no dice. Pedal is now difficult to press all the way down and PTO still not disengaging.

Anything else to try before I start tearing it down for a split? I'm assuming it's just seized up.

Anything else to try before I start tearing it down for a split? I'm assuming it's just seized up.