Bill Knecht

Member

Hi. It's been a while since I've been on this forum. Greetings, all.

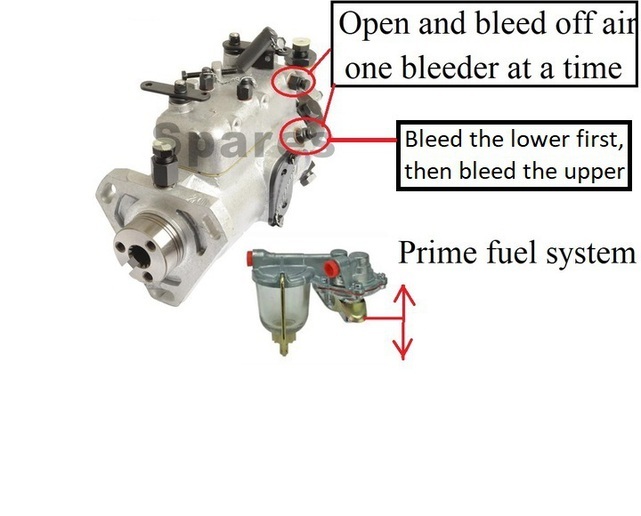

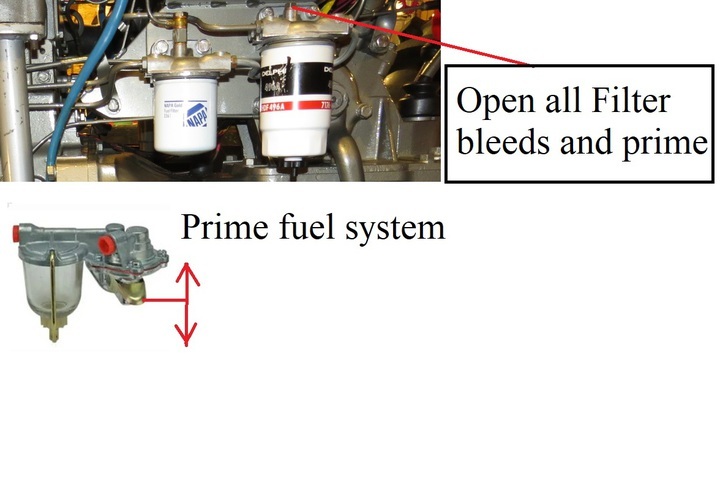

Got a problem with my 1074 MF135 perkins diesel. I was changing the lift pump & air got into the fuel lines. First time it's happened to me. So, following the Operator Manual, I started bleeding the system. Got as far as the top injector pump vent plug, but then stalled out at "Step 8", trying to loosen the injector connectors, My wrenches will fit on the connector, but there's no space in there for the wrench to move. Is there some special tool needed? If so, where can I get one?

Thanks. I'm stalled on this one. No amount of engine cranking seems to push fuel up that last little bit of line. It looks like I have to loosen those injector connectors. It's got me beat. Time to talk to you experts.

Got a problem with my 1074 MF135 perkins diesel. I was changing the lift pump & air got into the fuel lines. First time it's happened to me. So, following the Operator Manual, I started bleeding the system. Got as far as the top injector pump vent plug, but then stalled out at "Step 8", trying to loosen the injector connectors, My wrenches will fit on the connector, but there's no space in there for the wrench to move. Is there some special tool needed? If so, where can I get one?

Thanks. I'm stalled on this one. No amount of engine cranking seems to push fuel up that last little bit of line. It looks like I have to loosen those injector connectors. It's got me beat. Time to talk to you experts.