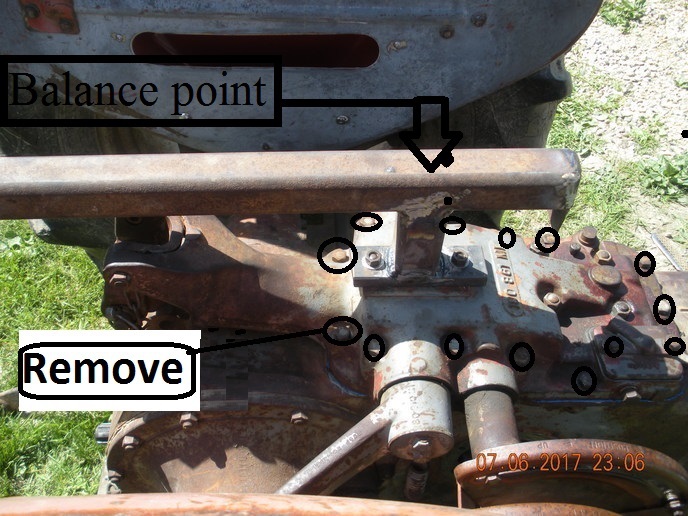

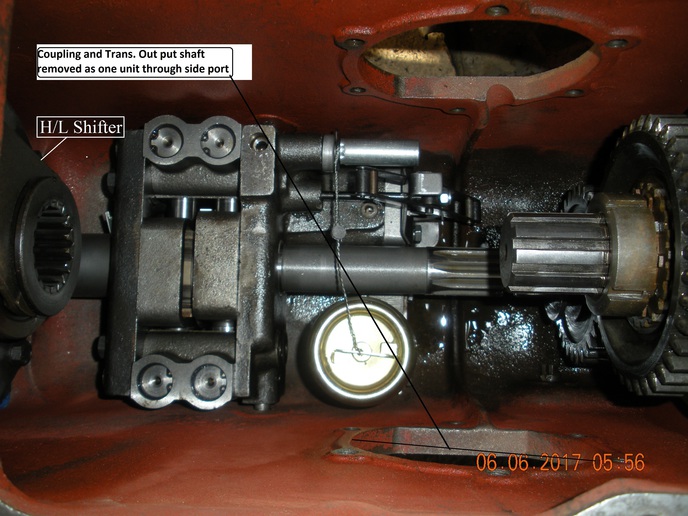

I have a Massey 65 MKII and last year I had a diverter valve with external remotes installed. On my diverter valve moving the valve arm to the left postition engaged the 3 point while moving arm to the right engaged my external hydraulics. Placing the valve arm in the center put it in this weird dead zone where the pump laboured but nothing happened. I'm assuming this shuts off the flow through the stand pipe but I'm not sure. After a winter of leaving the arm in the 3 point position to move round bales I decided to test the remotes out. They worked but while engaged I moved the diverter valve to the center to test the pressure (my mechanic did this so I assumed it wouldn't hurt anything). I felt the pressure for a second and all the sudden I felt it release, almost like something popped. I switched it back to my 3 points and now they won't lift. I took off the diverter valve and turned the tractor over and nothing came out of the stand pipe. Have I just bent myself over a barrel and done something to completely mess up my hydraulic pump? Any insight would be tremendously helpful!

Thanks!

Julian

Thanks!

Julian