FullPullLarry

Member

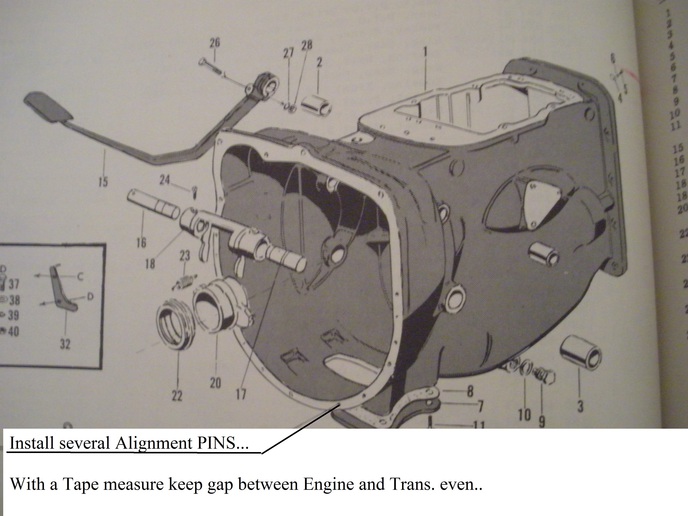

What fun it is to line up a Perkins diesel into my MF35 with the two clutch splines. Using the fork lift doesn't give me much play on the engine angle to get the pilot in the bearing correctly so the engine sits a couple inches away from the transmission. It should slide together easy if I could get the angle right. No amount of lifting and shaking up and down while the engine is hanging from the forklift does the trick to line the pilot up. I guess I'll have to get my engine crane. Any particular tips for lining up this transmission shaft combo with an engine...and yes I have a clutch tool.