Back in May I posted my problems with the hydraulic lift (kind of worked but wouldn't stay up) and the position control (didn't really work at all, just crude up or down with the draft control).

Posted pic of broken ram lug even though it seemed rock solid and DavidP wrote: "If the lug of the lift cylinder is broken that can be enough to prevent the position control working. The cylinder will lift in one corner and probably 'blow' the O ring."

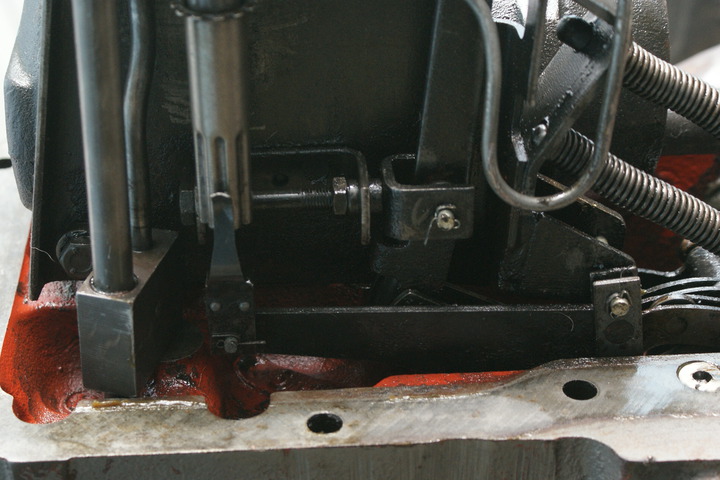

Have finally found the time to take off the cylinder and guess what I found? I think the pic is pretty self-explanatory: DavidP clearly has Xray vision that works long distance, impressive diagnosis! Many thanks David (also I did the control link tests you recommended and they checked out OK I think).

So, the questions:

1) The cylinder must obviously be replaced: should I take out the piston (how?) or get a new one?

2) The mounting bracket for the vertical control bar looks out of true (see pic), should I bend it square?

3) Anybody got any ideas how this happened? The broken lug has what looks like copper grease on it (see out-of-focus pic) so it was presumably reassembled broken ... also the bolts look like studs with nuts tacked on, and one of them is quite badly bent (!) had to be drifted out. Haven't looked for the broken lug, quess it could be in the sump somewhere ...

All comments and suggestions gratefully received.

Posted pic of broken ram lug even though it seemed rock solid and DavidP wrote: "If the lug of the lift cylinder is broken that can be enough to prevent the position control working. The cylinder will lift in one corner and probably 'blow' the O ring."

Have finally found the time to take off the cylinder and guess what I found? I think the pic is pretty self-explanatory: DavidP clearly has Xray vision that works long distance, impressive diagnosis! Many thanks David (also I did the control link tests you recommended and they checked out OK I think).

So, the questions:

1) The cylinder must obviously be replaced: should I take out the piston (how?) or get a new one?

2) The mounting bracket for the vertical control bar looks out of true (see pic), should I bend it square?

3) Anybody got any ideas how this happened? The broken lug has what looks like copper grease on it (see out-of-focus pic) so it was presumably reassembled broken ... also the bolts look like studs with nuts tacked on, and one of them is quite badly bent (!) had to be drifted out. Haven't looked for the broken lug, quess it could be in the sump somewhere ...

All comments and suggestions gratefully received.