In February got a diesel 135, engine seems great and I love it, but it's a first tractor and there's SO much I don't know… Have read some brilliantly useful posts on this forum but none with quite this collection of symptoms so I hope someone will forgive all these words and be able to offer some advice … I have grass that needs cutting soon!

Don't know the model year, can't find any info plate. Not a multipower. Don't know whether it's a 2 stage clutch: half of pedal travel is relatively soft, then suddenly requires more pressure. Sold to me as having PTO and hydraulics "as they should be" but after standing 3 months in cold weather, though covered, situation was as follows:

PTO seemed OK: with engine running and "engine" selected would turn when the tractor was stationery. With "ground" selected would turn when tractor moved. Hydraulics wouldn't lift any load.

So: dismantled quadrant controls, seemed properly connected to the internal linkages, control valve operation seemed fine, all the bits moved smoothly. Draft and position levers have no functioning stops or markers, draft tends to spring upright.

Cleaned hydraulic filter, thick with a sort of gluey gel, and it now lifts beautifully: manages a long, heavy topper without any problem at all. Hooray.

Put covers back (2 tries to get the PTO selector in the groove), replaced tranny oil, which seemed in good condition: brown, reasonably clear.

Current situation:

PTO: with lever at either "ground" or "engine" the output shaft only turns when tractor moves. This seems a backward step from when I got it! Presumably I've cocked something up. Drat.

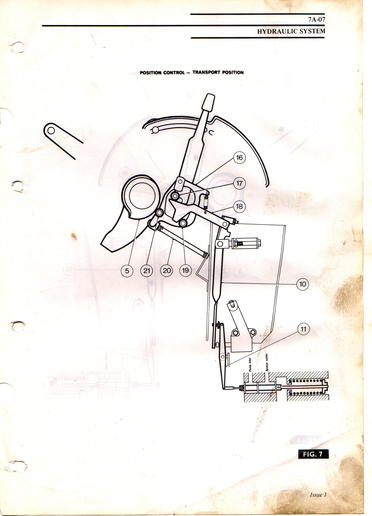

Hydraulics: lift goes up and down on the draft control only. Position control has no effect at all.

3 pt linkage stays up when engine is running, but sinks immediately engine is off.

3 pt linkage lowers when clutch is depressed, rises when released (I really don't get this bit).

There is a single output bobbin (?) hydraulic control under the driver's right thigh. It must be open (anti-clockwise) at least half a turn for the lift to work. There is a short output hose from it, ending in a socket which is weeping slightly.

There is a two-output hydraulic control on the left side, but the lever/switch won't turn at all (perhaps locked as there is nothing connected to the outputs?).

I have the operator's manual, but which workshop manual should I get?

Many thanks to anyone who's read this far ...

Don't know the model year, can't find any info plate. Not a multipower. Don't know whether it's a 2 stage clutch: half of pedal travel is relatively soft, then suddenly requires more pressure. Sold to me as having PTO and hydraulics "as they should be" but after standing 3 months in cold weather, though covered, situation was as follows:

PTO seemed OK: with engine running and "engine" selected would turn when the tractor was stationery. With "ground" selected would turn when tractor moved. Hydraulics wouldn't lift any load.

So: dismantled quadrant controls, seemed properly connected to the internal linkages, control valve operation seemed fine, all the bits moved smoothly. Draft and position levers have no functioning stops or markers, draft tends to spring upright.

Cleaned hydraulic filter, thick with a sort of gluey gel, and it now lifts beautifully: manages a long, heavy topper without any problem at all. Hooray.

Put covers back (2 tries to get the PTO selector in the groove), replaced tranny oil, which seemed in good condition: brown, reasonably clear.

Current situation:

PTO: with lever at either "ground" or "engine" the output shaft only turns when tractor moves. This seems a backward step from when I got it! Presumably I've cocked something up. Drat.

Hydraulics: lift goes up and down on the draft control only. Position control has no effect at all.

3 pt linkage stays up when engine is running, but sinks immediately engine is off.

3 pt linkage lowers when clutch is depressed, rises when released (I really don't get this bit).

There is a single output bobbin (?) hydraulic control under the driver's right thigh. It must be open (anti-clockwise) at least half a turn for the lift to work. There is a short output hose from it, ending in a socket which is weeping slightly.

There is a two-output hydraulic control on the left side, but the lever/switch won't turn at all (perhaps locked as there is nothing connected to the outputs?).

I have the operator's manual, but which workshop manual should I get?

Many thanks to anyone who's read this far ...