Norman Langford

New User

I am working on an MF 135 where the hydraulic lift arms have stopped operating. Firstly I was advised to check and the clean the hydraulic oil filter. The lift arms, by the way were in the halfway up/down position. When I positioned both the Draft Control Lever and the Position Control Lever in their lowest positions to drain all of the hydraulic the oil, I noticed that the lift arms stayed in the same position whereas I would have expected them to drop to the lowest position.

I carried out the filter cleaning process without a problem, in fact the filter was not in the slightest dirty, but cleaning the filter had no effect on the problem. However I did notice that with the Draft Control and Position Control levers still in the down position, when the tractor was started up the lift arms rose to the high position and I could hear the oil pressure release valve operate when the arms reached the highest position. It then did not matter what positions I placed either of the levers in, the lift arms remained at their high position and would not move. However when the engine was switched off, standing on the lift arms caused them to drop to the lowest position irrespective of the position of the two levers. Again starting the engine caused the lift arms to rise irrespective of the position of either lever.

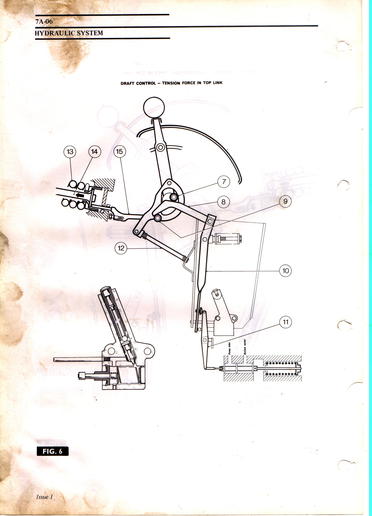

I figure that the problem is not with the pump, but something to do with the control valves operated by either the Draft Control lever or the Position Control lever, but I have no idea how to go about identifying the cause of the problem or how to rectify it. I would therefore appreciate and help I can get with this issue.

I carried out the filter cleaning process without a problem, in fact the filter was not in the slightest dirty, but cleaning the filter had no effect on the problem. However I did notice that with the Draft Control and Position Control levers still in the down position, when the tractor was started up the lift arms rose to the high position and I could hear the oil pressure release valve operate when the arms reached the highest position. It then did not matter what positions I placed either of the levers in, the lift arms remained at their high position and would not move. However when the engine was switched off, standing on the lift arms caused them to drop to the lowest position irrespective of the position of the two levers. Again starting the engine caused the lift arms to rise irrespective of the position of either lever.

I figure that the problem is not with the pump, but something to do with the control valves operated by either the Draft Control lever or the Position Control lever, but I have no idea how to go about identifying the cause of the problem or how to rectify it. I would therefore appreciate and help I can get with this issue.