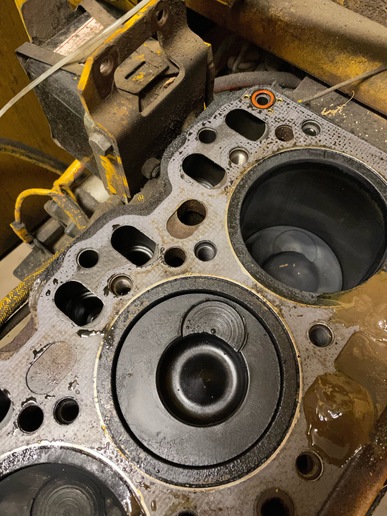

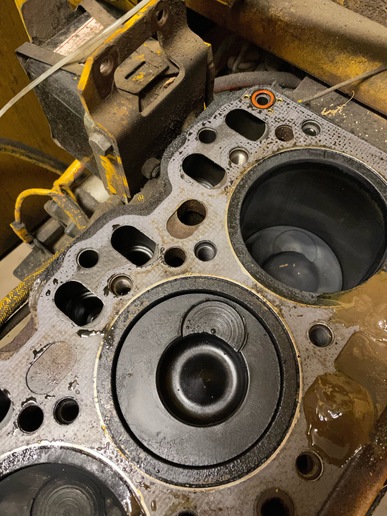

Ok. Spent some bucks doing an in-frame rebuild on my 310 B. The machine shop completely redid the head with new valves and the works. Put in piston liners with new pistons and rings. Fairly quickly started with blow by. Compression test showed subnormal compression. (350 recommended, all shooting 280 to 325. Tractor seemed to run ok but oil from breather soon became a torrent. Tore head off today and found a 5 mm indent on all aluminum cylinders in exact location of exhaust valves. Exhaust valves sat proud of the head surface 4 to 5 mm as well.

Of course machine shop saying not my fault. Had 3 different professional opinions today from Deere certified mechanics. All say machine shop error. Few explain blow by. One says the pistons, connecting rods, and bearings should be replaced.

Your thoughts????

Of course machine shop saying not my fault. Had 3 different professional opinions today from Deere certified mechanics. All say machine shop error. Few explain blow by. One says the pistons, connecting rods, and bearings should be replaced.

Your thoughts????