I had a previous post from last year about this problem and found the main issue I believe?

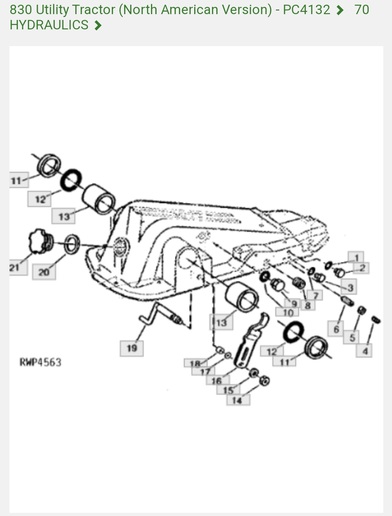

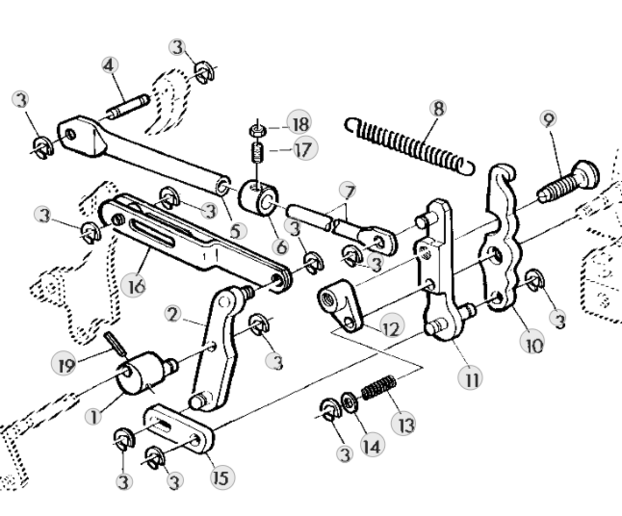

So this spring I decided to use my box blade only to realize that my lift arms would barely raise the implement. I had to look under the rockshaft housing which was the plan anyway. Once lifted I immediately found the issue from my main question. The cam follower arm had broken off and landed in the catch pan behind it, thank goodness it didn't land on any gears. The lift arm linkage was also bent some, part #19 in drawing, so I straightened that without having to remove it. I may have also fiddled with the slotted adjusting screw for the lifting and lowering valve clearances to the cam linkage, so I'm going to set it proper to make sure the valves aren't being preloaded and bleed by.

My question is, with these two main things being known issues. Could this be the main reason I'm not getting lift at any load setting, or is it advisable to rebuild some of the other parts like the cylinder and or valves? Taking the housing off again, is pretty simple with an engine hoist but before this linkage and cam follower problem, the lift arms lifted with great force and proper speed?

Thanks in advance.

So this spring I decided to use my box blade only to realize that my lift arms would barely raise the implement. I had to look under the rockshaft housing which was the plan anyway. Once lifted I immediately found the issue from my main question. The cam follower arm had broken off and landed in the catch pan behind it, thank goodness it didn't land on any gears. The lift arm linkage was also bent some, part #19 in drawing, so I straightened that without having to remove it. I may have also fiddled with the slotted adjusting screw for the lifting and lowering valve clearances to the cam linkage, so I'm going to set it proper to make sure the valves aren't being preloaded and bleed by.

My question is, with these two main things being known issues. Could this be the main reason I'm not getting lift at any load setting, or is it advisable to rebuild some of the other parts like the cylinder and or valves? Taking the housing off again, is pretty simple with an engine hoist but before this linkage and cam follower problem, the lift arms lifted with great force and proper speed?

Thanks in advance.