Well, since I have searched the internet long enough without getting the answers I need, I figured it was time to try asking someone here. I'm hoping there is a big enough 2 cylinder fan club on here so I can get somewhere with my 1940 B (s/n# 95050). this is my first "gasser" restoration. I've done a handful of diesels, and after this B, I might just keep it that way. but I must say, parts are waaayyyy cheaper for B's compared to my 820. But, anyways, I found 2 B's sitting in the weeds, bought them figuring i could get them running and make a few bucks. Pretty sure I'll be lucky to break even after this one. Cylinder block had a major hole in it so i machined a plug and brazed it shut, then had it honed. The block has new valves, and has been surfaced, put the stock pistons back in with new rings. I went through the carb and completely revamped it with Steiner's deluxe carb kit. bought a new magneto, and put a new radiator core in it. ever want to pull your hair out, try resealing the cooling system on that thing... I have another question pertaining to that topic too, but firstly, this whole timing issue is making me want to part this thing out and give up.

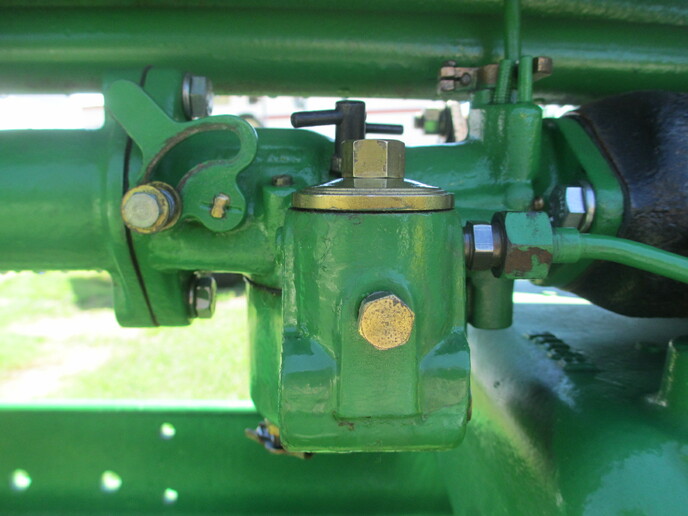

So, for the real question, who knows which timing cup my B needs and where the impulse mark needs to be at inside the Magneto? bought a refurbished WICO C Magneto off eBay. has a short lug 25 degree drive cup on it(says 25 degree with the part #6274 i believe), but there is no part number on the old one(also a short lug), and I'm wondering if it is a 35. when I timed the mag and got it running it did run, but not great, it sputtered and missed. But did not backfire to the best of my recollection. Watched a lot of "justtinkering" on YouTube. afterwards it was suggested that I rotate my governor gear one tooth backwards, or clockwise. tractor did run better, but still not great, went another tooth and it couldn't get it to start. went back to one tooth and fired up to run half way decent. while it was running, I twisted the mag clockwise(top of mag towards front of tractor) and it seemed to run slightly better yet. this has led me to believe that i have the wrong drive cup on my Magneto. When starting it currently, it doesn't take much to get it fired up, about 4 pulls on the flywheel. Does anyone have any better insights? Love testing out ideas and fixing it all myself, but I'm starting to get tired of getting nowhere.

So, for the real question, who knows which timing cup my B needs and where the impulse mark needs to be at inside the Magneto? bought a refurbished WICO C Magneto off eBay. has a short lug 25 degree drive cup on it(says 25 degree with the part #6274 i believe), but there is no part number on the old one(also a short lug), and I'm wondering if it is a 35. when I timed the mag and got it running it did run, but not great, it sputtered and missed. But did not backfire to the best of my recollection. Watched a lot of "justtinkering" on YouTube. afterwards it was suggested that I rotate my governor gear one tooth backwards, or clockwise. tractor did run better, but still not great, went another tooth and it couldn't get it to start. went back to one tooth and fired up to run half way decent. while it was running, I twisted the mag clockwise(top of mag towards front of tractor) and it seemed to run slightly better yet. this has led me to believe that i have the wrong drive cup on my Magneto. When starting it currently, it doesn't take much to get it fired up, about 4 pulls on the flywheel. Does anyone have any better insights? Love testing out ideas and fixing it all myself, but I'm starting to get tired of getting nowhere.