RoeFarmall

Member

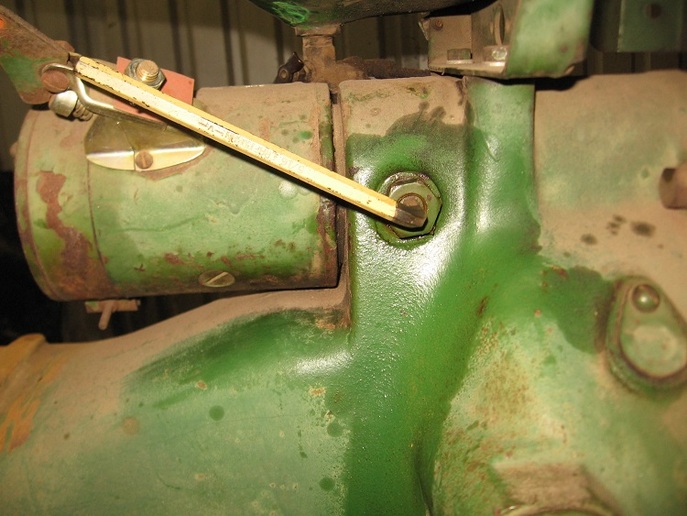

I am working on my next project, a 1947 John Deere "M". I have determined that the starter is bad and needs to be rebuilt. When I turn the nut which turns the mounting set screw for the starter, the set screw "shaft" sheared off flush with the frame. Upon further inspection, it looks like the previous owner tried to drill out the set screw and gave up. I have two pictures to show the result. What do you suggest that I do to get the "set screw" out so I can replace or rebuild the starter?

My thanks in advance

My thanks in advance