You should upgrade or use an alternative browser.

- Thread starter SVcummins

- Start date

cornerpost

Member

tomstractorsandtoys

Well-known Member

wore out

Well-known Member

(quoted from post at 21:00:59 08/05/20) Can isolate just one scv on this tractor

After the tractor has cooled off overnight, start it and listen for rushing/flowing noises at all the high pressure hydraulic components and note the temperature rise at each as the machine warms up.

A component with an internal "high pressure leak to sump" will be making noise and will warm up faster than the tractor chassis.

An "infrared heat gun" is helpful for this. The SCV's, steering valve, brake valve, and hitch valve shouldn't get warm(er) any quicker than the main transmission case so long as none of those functions are being used.

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

Yes you'll need new quad rings(2 ea- R26149) & 3 ea-3/8" X 3-1/2 cap screws

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

(quoted from post at 09:38:33 08/07/20)

Still doesn t explain why the pump isn t making any pressure

Only way to correctly answer that question is by utilizing good hyd diagnostic procedures!!!!! Large internal high pressure leak can rob frt pump of pressure because trans pump doesn't have the ability to furnish enough oil.

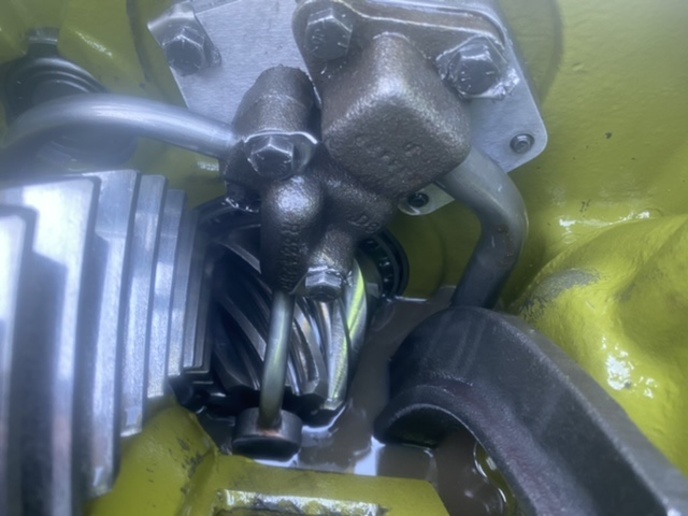

circuit, new pump new gaskets new orings started the tractor

with rockshaft housing off can’t see any oil spraying out of

anywhere no leaks ? Plumbed the external hydraulic valve in

rider and that seemed to fix the problem but it to has an

external leak because it gets hot hot hot and you can hear the

oil bypassing the valve inlet hose and drain hose and even

main hydraulic cylinders get very hot but it still works better

than off the tractor scvs .

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

When you checked trans pump pressure/flow what were the readings? Have you checked hyd operation with each hyd component individually capped off?

valve closed . I capped the three point Off no change capped

the scvs off and plumed loader through my external valve and

the loader worked great for a few minutes until the oil and

valve got hot it has an internal leak you can here the oil

bypass inside the valve with it in neutral I put a conversion

plug in it to change from open center to closed center but it

had other problems internally.

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

Have you checked hyd filter relief valve to be sure it's not stuck open?

buickanddeere

Well-known Member

The loader control valve has been operated open centre until now ?

now even with the loader valve the way it is it still works Better

than it was on the scvs ran the loader off the scvs since 2005

this winter it started taking longer and longer for the hydraulics

to start working so I tested the transmission pump decided

was bad changed it worked better but still not right . Number

one scv gets hot after about 5 minutes of idling

buickanddeere

Well-known Member

Sounds like those SCV need to be setup on TimSs calibration bench . The setup he has there Is the best that I have seen in a long time .

johnyquest69

Member

feel the oil and hear it bypassing the valve and the valve gets

so hot after about 5 minutes you can’t touch it so I know it’s

bypassing even though it shouldn’t but the valve is 50 years

old so it could have an issue at the end of the day even with

the valve leaking it still works better than it did when hooked

up to the tractor scv .

wore out

Well-known Member

(quoted from post at 14:45:16 08/09/20) I ordered a plug to change the valve and it didn t work I can

feel the oil and hear it bypassing the valve and the valve gets

so hot after about 5 minutes you can t touch it so I know it s

bypassing even though it shouldn t but the valve is 50 years

old so it could have an issue at the end of the day even with

the valve leaking it still works better than it did when hooked

up to the tractor scv .

You are saying it's bypassing in the valve mounted on the loader, correct?

Most likely, there's a relief valve in that valve and it isn't set high enough to contain the 2250 PSI from the tractor.

Crank that relief down as tight as it will go, it isn't needed with your closed-center system because the controls on the 4020's hydraulic pump take care of limiting hydraulic pressure.

Just the OPPOSITE of how things would work if that loader was fed from an open-center PTO pump, in which case the relief in the loader valve is DEFINITELY needed.

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

Ditto about what wore out stated about relief valve.

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

Same scv utilized on early model 3020 & 4020.

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

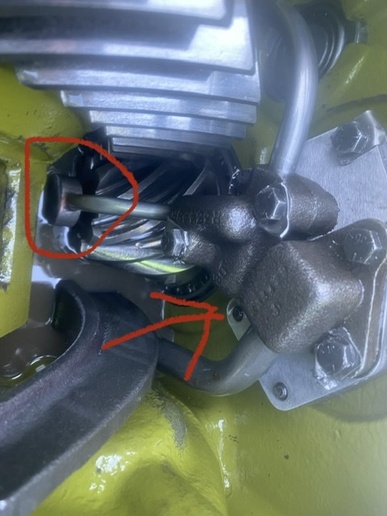

I suggest removing Closed center plug to check to be sure internal seal on plug is not blown!!

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

(quoted from post at 21:41:46 08/11/20) The plug they sent me didn t have a seal it s just more of a

cap so maybe it s not the right thing but it s what the farmhand

book showed

I learned by the difficult method way back 50 yrs ago if the inner seal FAILS on closed center plug shown in photo below then closed center hyd's will not function as designed!

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

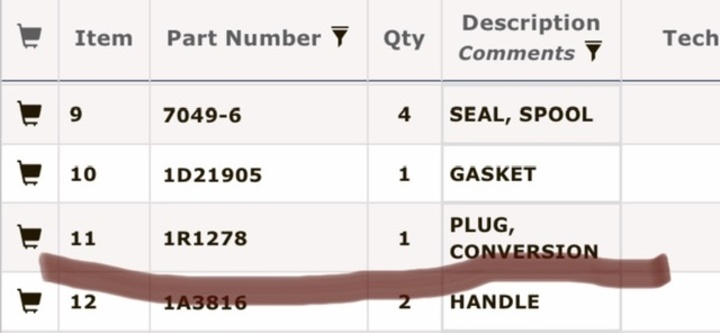

All closed center conversion plugs(key 12A or 12B) I've ever seen resemble the plug in the photo I previously posted. You probably have an open center plug(key 12C) that was utilized before "power beyond" was created.

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

IIRC control valve in parts schematic is a Gresen brand & closed plug from JD is NLA. I found the closed center plug in photo below but it's for a Prince valve & I'm not sure it will fit your valve.

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

If your control valve is a Gresen then Bailey Hyd's shows to have a CC plug for model SP,SPK & SSK control valve.

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

Tx Jim

Well-known Member

- Location

- Coyote Flats, Texas

It's immaterial what implement your valve came with or what type pump supplied pressure for it. I'll bet there's a closed center plug that will fit it.

wore out

Well-known Member

(quoted from post at 12:19:25 08/14/20) Cannot get a plug from gresen . Going to see if farmhand can get one if not Bomgaars has a 2 spool valve thats rated 30 gpm and 3000 psi

I think I figured out what's going on... The way it's set up you need the "power beyond" plug because there's a second valve, but the "power beyond" plug doesn't work with "closed center". The fix would be to get the "closed center conversion plug" and eliminate the second valve. (IF you can live without the third spool.)

It's possible there's a "closed center conversion plug" available for the second valve, if so you could install that and "T" the pressure line from the tractor to the inlets of BOTH valves.

That's how closed center systems work, a common pressure line is "T'd" to all valves, the opposite of an "open center" system were valves are in series.

Similar threads

- Replies

- 8

- Views

- 254

- Replies

- 4

- Views

- 146

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy