Ok, I'm at the end of my rope. The pivot pin has wallered out it's threads so badly that the oil runs out as fast as you pour it in.

I tried drilling it out to 7/8 and tapping for 1" threads, but the 7/8 bit (originally 7/8 thread) just went through. I ordered a 15/16 bit and tried it again today. Bit screwed itself in and stuck. Ended up bending the shank trying to get it out. It never came out. Have to go back at it with a 2' pipe wrench to see if I can get it out.

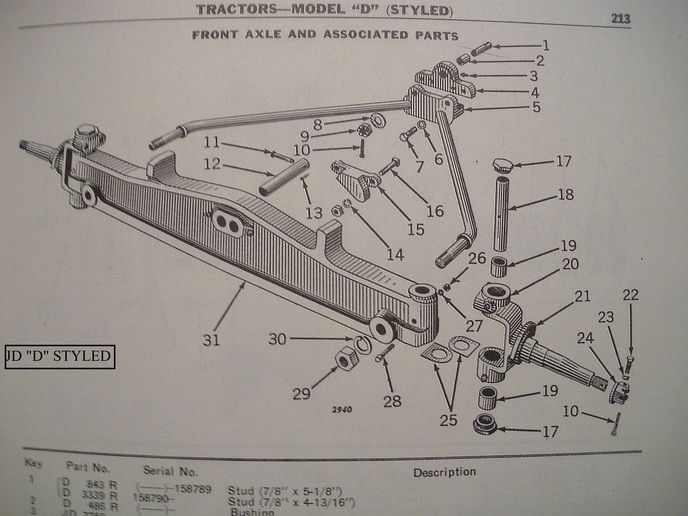

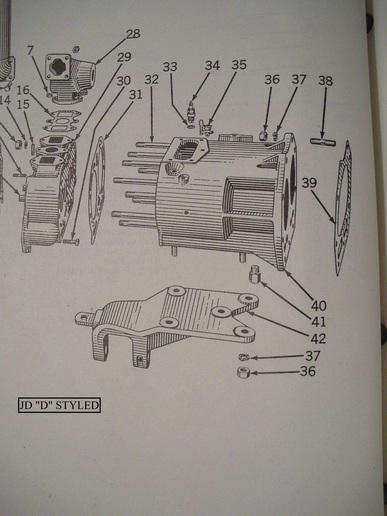

If I get it out without having to melt it out, what's my next option? Is the inside of the housing flat enough that I could clamp a rubber washer under a bolt head in the inside? If so, then I would have to mill down the pivot for the front axle by the thickness of a nut since it would have to grab the case super tight to prevent oil leakage. Would that cause strength issues?

Any other thoughts?

I tried drilling it out to 7/8 and tapping for 1" threads, but the 7/8 bit (originally 7/8 thread) just went through. I ordered a 15/16 bit and tried it again today. Bit screwed itself in and stuck. Ended up bending the shank trying to get it out. It never came out. Have to go back at it with a 2' pipe wrench to see if I can get it out.

If I get it out without having to melt it out, what's my next option? Is the inside of the housing flat enough that I could clamp a rubber washer under a bolt head in the inside? If so, then I would have to mill down the pivot for the front axle by the thickness of a nut since it would have to grab the case super tight to prevent oil leakage. Would that cause strength issues?

Any other thoughts?