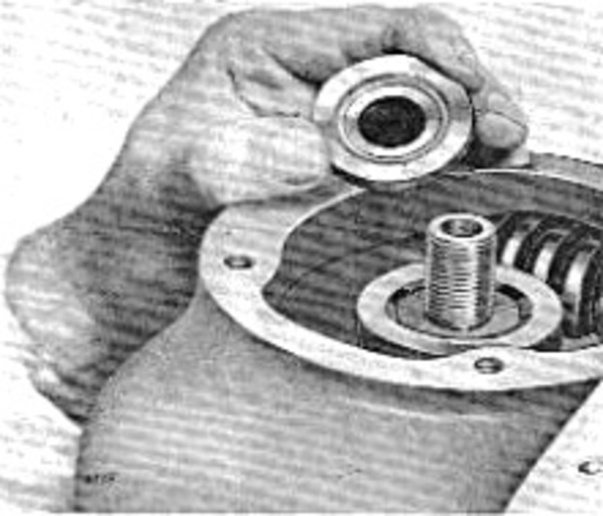

I am working on a 1950 John Deere A and have a question regarding servicing the steering box. How tight is the 1 5/16" castle nut supposed to be that holds the sector gear down. Is it supposed to be extremely tight in order to firmly hold the gear to the splines? Or is nut supposed to adjusted more like a wheel bearing system should be (i.e. hand tight and then back off a 1/8 or 1/4 turn or so) since this shaft also runs through the pedestal vertically as the main pivot axle. I have the parts list and owners manual, but can not tell if that lower bearing is a taper bearing or a roller type bearing so not sure how to tighten this nut.

FWIW: I have already searched and have found lots of helpful info in regards to servicing the gearbox. I have already pulled the sector gear for visual inspection and it was in surprisingly good shape. I re-installed the sector and adjusted the eccentric bushing and was able to remove almost all of the slop and everything still turns freely from to lock to lock. Worm shaft end play was good and did not need any adjustment.

FWIW: I have already searched and have found lots of helpful info in regards to servicing the gearbox. I have already pulled the sector gear for visual inspection and it was in surprisingly good shape. I re-installed the sector and adjusted the eccentric bushing and was able to remove almost all of the slop and everything still turns freely from to lock to lock. Worm shaft end play was good and did not need any adjustment.