Usually if she motors just fine (field grounded or not) that tells me basically the Armature and Brushes are good PROVIDED she motors fast n smooth n even RPM. (still could be an armature problem which takes a growler as Bob noted)

Next if you motor it with the field dead grounded to case frame but she DOES NOT speed up a bit when you unground the Fields, then I suspect a field problem which can cause her to NOT charge.

Typical Field problems may be one of the coils is shorted out to case somewhere,,,,,,,,its shorted to case (or broke open) where the 2 fields splice in the middle,,,,,,,,,,the Field terminal post has been overtightened making the Field ALWAYS grounded and she would always be in max high charge,,,,,,,,,,shes overtightened and the field wire is broke off from the terminal (non charging and no PRM motor speed change),,,,,,,One of the fields is OPEN

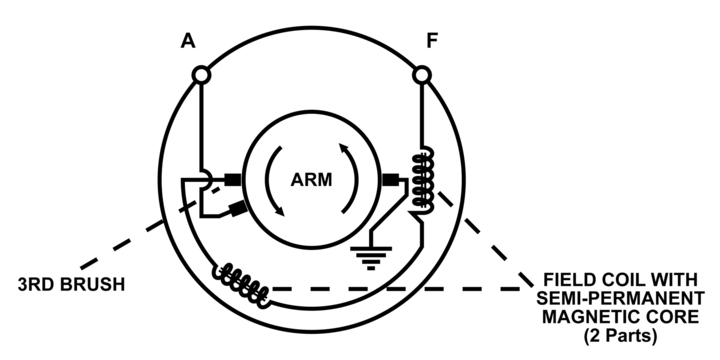

If you ohms out the fields, Id expect maybe 3 to 6 ohms or so (for the 2 in series), if zero theres a field short, if open its open and bad. Obviously the fields termination must be present at the FLD post while their beginning is at the third asjustable/moveable brush

Id say a genny can still charge if you swap the brush wiring, but I still (until proven otherwise) stand on my earlier (and Bob agrees) post that the MAIN FIXED NON GROUNDED BRUSH is what attaches to the ARM post (other main brush is grounded) while the beginning of the Fields is what wires to the third adjustable/moveable brush. That way you increase field current for more output if the third brush is close to the main fixed brush while the gennys output is across the commutator at 180 from the other main grounded brush.

I think you have a field problem (shorted or open) and the main fixed brush is what wires to teh ARM post buttttttttttttt its your tractor n youre free to wire it as you please.

I agree with Bob the best way to test the armature is with a growler as my Motor test is still just a shadetree mechanics approach NOT perfect

let us know

Of course if Im wrong and the ARM wires to the adjustable third brush I will eat humble pie but I may not like it lol, Im never too old to learn. Again I say it can still work that way however

John T