[email protected]

Well-known Member

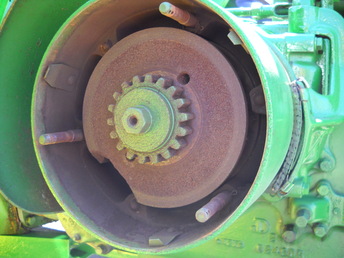

I have the service manual for my project tractor, BUT... Its not super clear on diagram and direction from what I see to what I would like to know. The clutch driver appears to have only a splined shaft with a locking bolt on the end, is there anything else that needs to be removed other than the obvious? There is no other dogs or pins anywhere that I am not seeing is there. I am trying to get a good idea on the entire project before I go ripping into something. I have the friction disk and that is the main reason that I want to get into it. 57 years and never a clutch, its time.