Well, if the brushes are shot not much use in running the "full field tests" now. See below

As far as the condition of the existing in place Field windings, an ohmmeter can tell ya if they are open or shorted to frame/case i.e. theres gotta be CONTINUITY through the two windings, but there CANT BE ANY SHORT FROM EITHER TO CASE/FRAME.

If the armature were removed, if you place an ohm meter on the R x 1 scale there should be CONTINUITY from the gennys FLD post over to its ARM (fields are wired between those two posts)post and that should be the sum of the two windings, maybe in the vicinity of 3 to 6 ohms or so depends on the gennys voltage, but it should still be a few ohms and CONTINUOUS otherwise, one of the windings is open or the splice is open where the two windings join together (can happen).

Next place one meter lead on the FLD and ARM posts and (with armature removed) there should be an open circuit to the other lead on the frame case OTHERWISE ONE OF THE FIELDS IS SHORTED OUT TO THE FRAME

If the armature were in place and if it and the brushes and commutator etc were all good, place one ohm meter lead on the frame case, and there would be very low ohms (almost short) on the ARM post but maybe 3 to 6 ohms on the FLD post cuz it has to go throught the fields before getting to the ARM post.

The fields begin at the ARM post,,,,,,,,splice in the middle, terminate out the FLD post...

Heres that full field test you can run with the brushes in place and the tractor running and the Motor Test for when shes NOT running..

TO DETERMINE IF ITS A GEN OR VR OR CUTOUT RELAY PROBLEM

5. a) VOLTAGE REGULATOR SYSTEM: With the tractor running, temporarily ground the Gens Field post to case. If she charges then but NOT otherwise, the VR may be bad, or a wires missing from VR's Field post to the Field terminal on the VR, or the VR isn’t well grounded.

b) IF IT’S A CUTOUT RELAY SYSTEM and she charges only if you dead ground the Field but NOT otherwise, its either a bad switch or the switch isn’t well grounded or else the wires bad or open from the Gens Field post up to the switch. INSURE THAT GOOD SWITCH GROUND AND WIRING

6. If she still don’t charge, leave the Field grounded and jump a wire across from the VR or Cutout Relays BAT terminal over to its GEN terminal (jump by passes the cutout relay) and see if she charges. If then but not otherwise, a VR's cutout relay isn’t working correct (maybe points burned/carboned) or a Cutout Relays NOT working or not wired correct.

7. With the 2 steps above, you have basically by passed the VR or Cutout relays functions, so if she still don’t charge, you're left with a bad battery or wiring or the Gen itself.

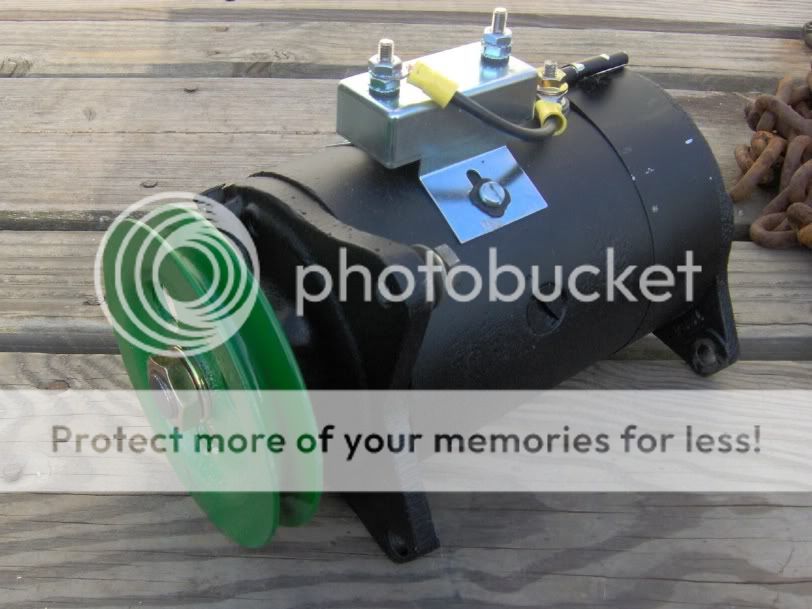

8. MOTOR TEST. You can Motor test the Gen. If its grounded and you remove the belt and apply hot battery voltage direct to its ARM Post and have the Field Post dead grounded to frame, it should motor n run well (Armature n Brushes and Commutator likely okay). Then, if you next remove the Fields ground and it speeds up some, the Fields probably good. If it passes both those tests, it should charge, and if not, it may be a wiring or battery or grounding problem. The hot battery voltage may be taken off the VR's BAT terminal or the starter post or the battery itself for this test.

If youre installing new brushes I would also clean n polish the commutator,,,,,,,be sure the armature isnt shorted,,,,,,clean n light lube the bushing,,,,,,,Polarize the genny before you start her up,,,,,,check all wires and wiring and terminal and insure BOTH the Genny and VR have good grounds

Nuff said

John T