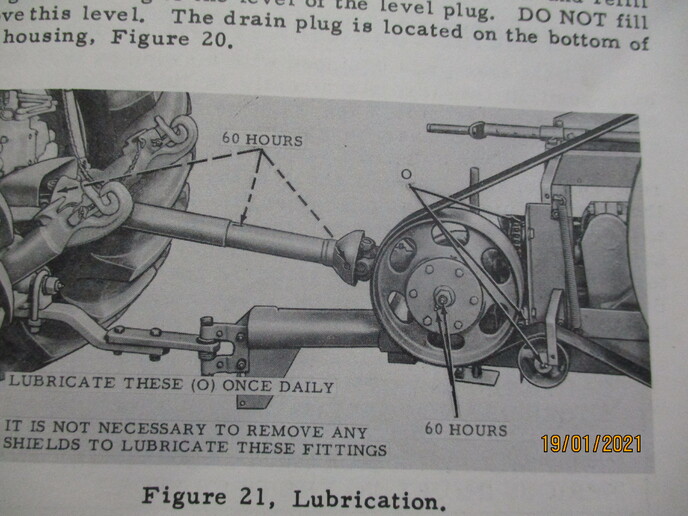

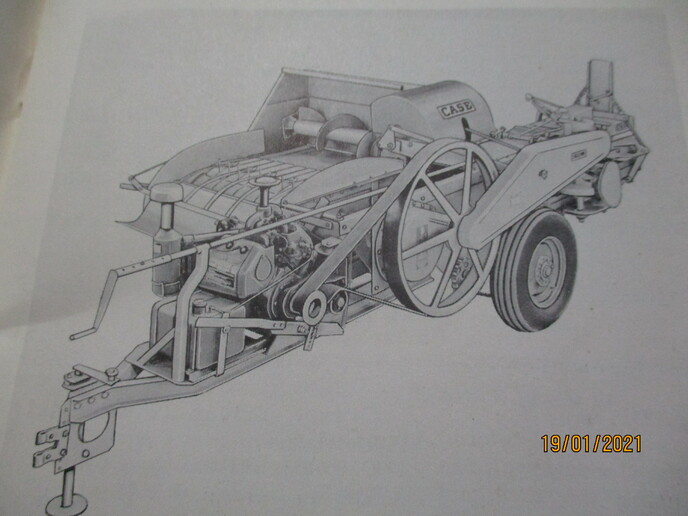

someone has a very old case baler for sale, looks like the pto goes to a 16inch dia. wheel, then there is supposed to be a belt to

a very large flywheel,, idk, would maybe try to restore it,, but looks like the smaller dia. wheel is supposed to have a rubber

outside, that is nearly totally missing,, am i right about the power feeding from the first wheel to the large wheel? otherwise

the whole thing looks to be in descent shape. cheap

a very large flywheel,, idk, would maybe try to restore it,, but looks like the smaller dia. wheel is supposed to have a rubber

outside, that is nearly totally missing,, am i right about the power feeding from the first wheel to the large wheel? otherwise

the whole thing looks to be in descent shape. cheap