charles todd

Well-known Member

This is my Root Rake or Ridgid Harrow I built recently. It has been too wet to use this past week. Here are some construction and finished pictures of my rake. Tell me what you think...

I appoligize for the size of this post. It may take a minute for the pictures to load on a slower connection.

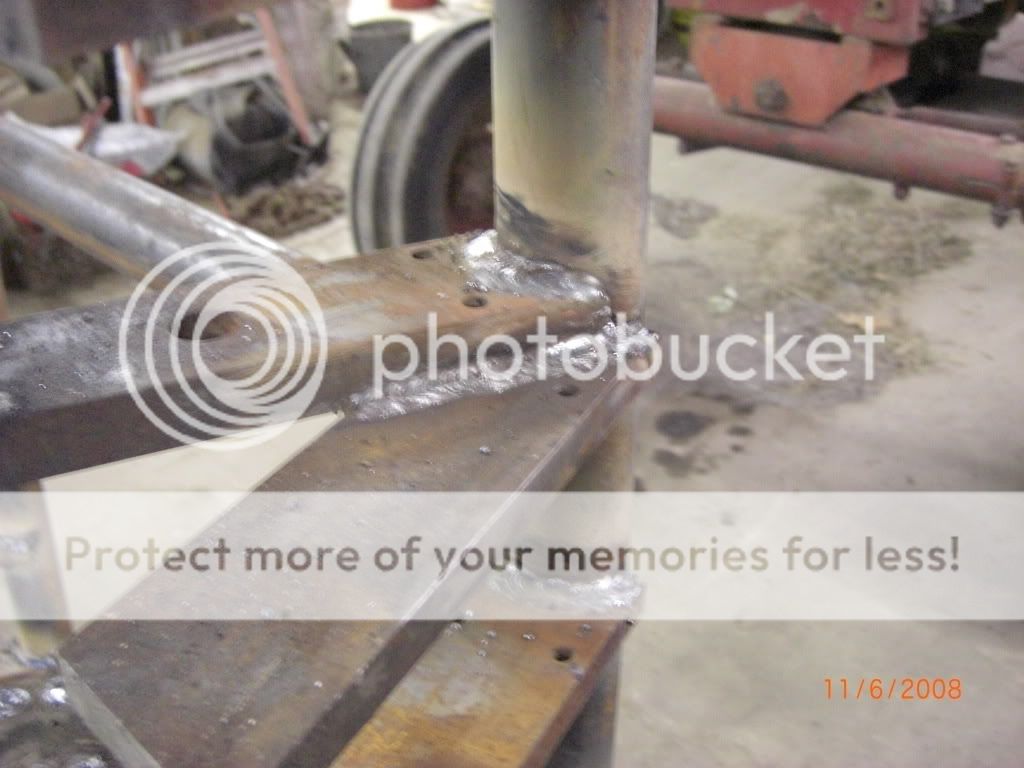

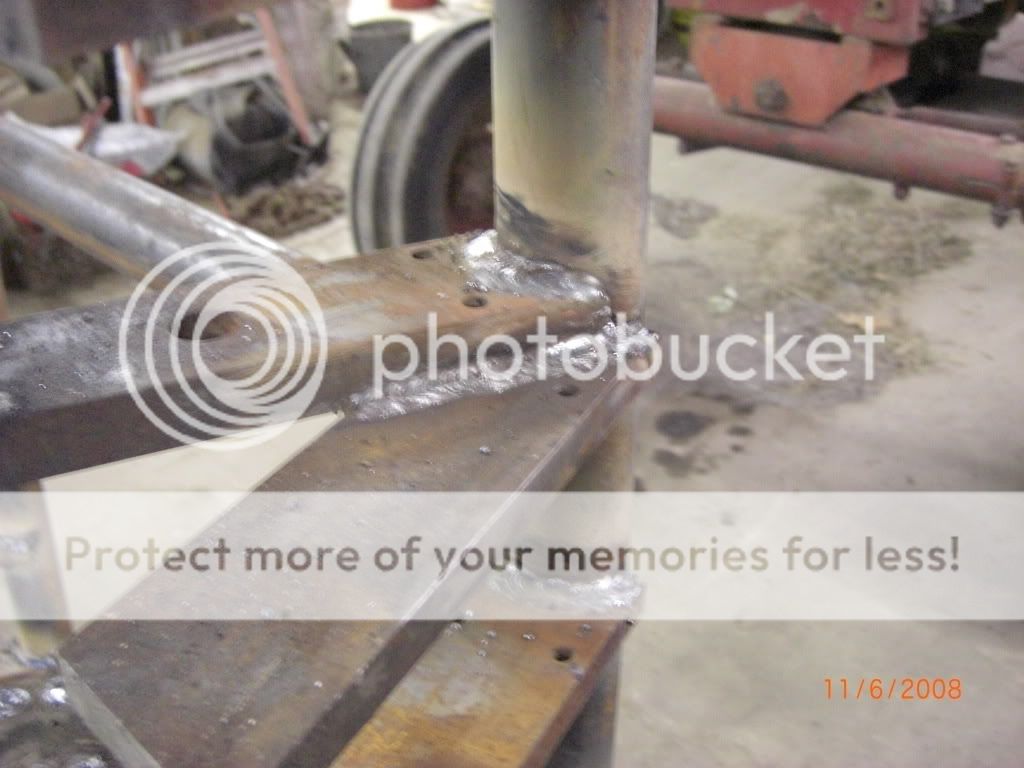

[b:8b0c81b7d6]Construction Phase[/b:8b0c81b7d6]

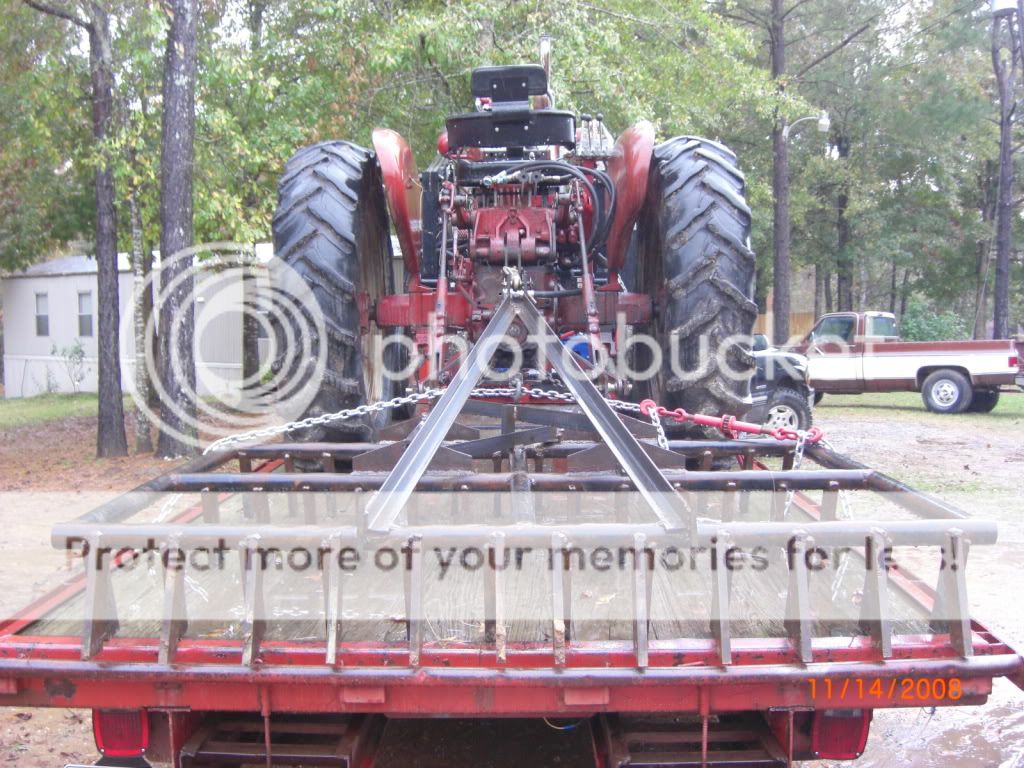

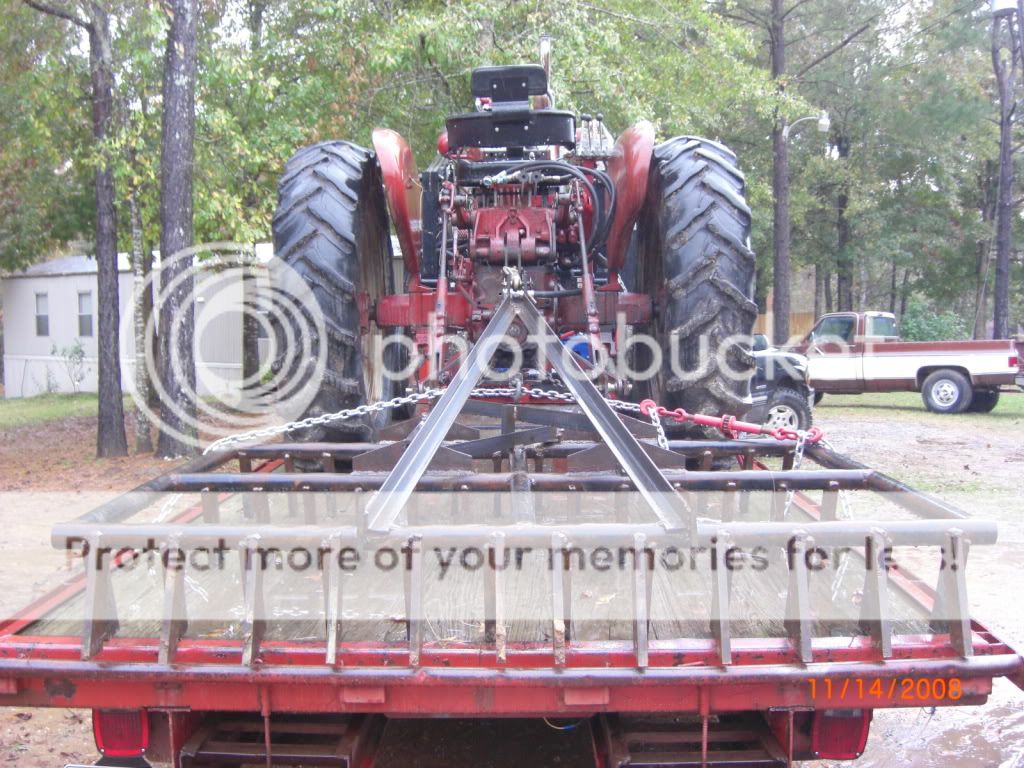

[b:8b0c81b7d6]Finished and on trailer at home...[/b:8b0c81b7d6]

[b:8b0c81b7d6]What I have to work with...[/b:8b0c81b7d6]

My Photobucket site is:

http://s262.photobucket.com/albums/ii89/nsula_country/

I am always adding pictures to this site.

Thanks guys, Charles

I appoligize for the size of this post. It may take a minute for the pictures to load on a slower connection.

[b:8b0c81b7d6]Construction Phase[/b:8b0c81b7d6]

[b:8b0c81b7d6]Finished and on trailer at home...[/b:8b0c81b7d6]

[b:8b0c81b7d6]What I have to work with...[/b:8b0c81b7d6]

My Photobucket site is:

http://s262.photobucket.com/albums/ii89/nsula_country/

I am always adding pictures to this site.

Thanks guys, Charles