kennytractor

Member

I have a two cylinder Kolher Courage 23hp engine. I noticed it is about one inch over full on the dipstick after sitting over the winter.

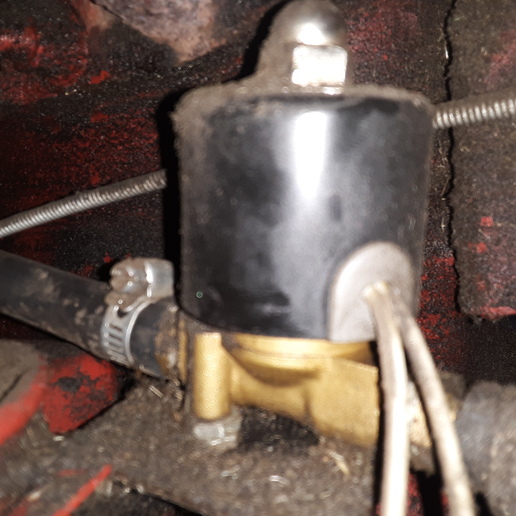

The fuel pump sits directly above the valve cover. This is where the pulse line is connected. Is it possible for gas to leak into the valve cover through the

pulse line? Is there a way to test the pump?

Engine starts and runs fine like it always has. Maybe I just need to clean the carburetor.

The fuel pump sits directly above the valve cover. This is where the pulse line is connected. Is it possible for gas to leak into the valve cover through the

pulse line? Is there a way to test the pump?

Engine starts and runs fine like it always has. Maybe I just need to clean the carburetor.