I have a 19HP Kawasaki with a 1" diameter shaft. I cannot get the PTO clutch off. Of course the videos online show it pulling right off after removing the bolt and retainer.

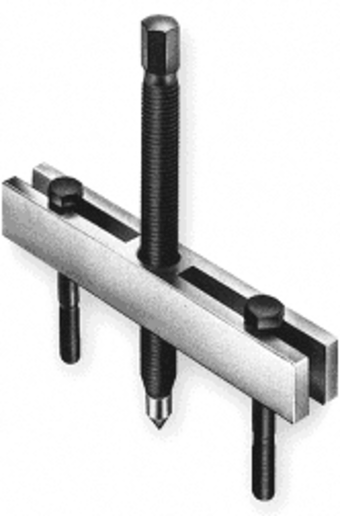

I have soaked it in penetrating oil; applied heat; used an air hammer on the inner bearing sleeve, and wedged a long pry bar behind it using the weight of the mower on the handle. It will not budge. I can't figure out how to get a bearing or gear puller on it.

I am to the point of cutting it off (doesn't look like a great option). Are there any other methods that I have not thought of? All help/suggestions are appreciated.

Thanks in advance,

Thad

I have soaked it in penetrating oil; applied heat; used an air hammer on the inner bearing sleeve, and wedged a long pry bar behind it using the weight of the mower on the handle. It will not budge. I can't figure out how to get a bearing or gear puller on it.

I am to the point of cutting it off (doesn't look like a great option). Are there any other methods that I have not thought of? All help/suggestions are appreciated.

Thanks in advance,

Thad