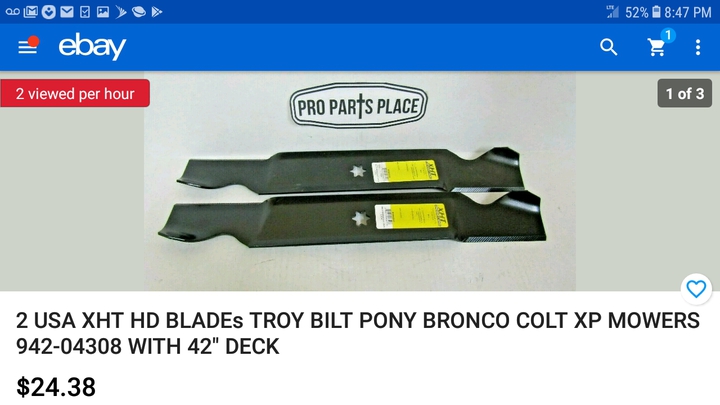

I bought a set of these blades a couple of weeks ago. They are tougher than regular blades. I have done some pretty heavy duty mowing on several lawns and a long in the standing overgrown side lot of about 1 1/2 acre size. The darn things are still sharp!!!! Think I might by a set for my other machines. Come in different styles and sizes. Very pleased with them. Just to try them out, buy yourself a set. Think that XHT stands for extra hardened tempered. Others I have seen, they weld a bead of hard temper welding rod along the bottom side of the blade. That keeps them sharp. Kinda like the blade on a Samurai sword . Here is a little blurb on them.