I will soon be tackling the hydraulics on my 61 Super Major and I want to confirm that I will be able to run the external hydraulics I have

acquired for the tractor.

I have a front end loader setup with four dual acting cylinders and an external directional control valve, a dual acting PTO mounted wood

splitter, and a PTO mounted snowblower with dual acting cylinder for the chute.

I am not entirely sure how to plumb the system. I have two complete FSM 3pt hitch lift covers, hydraulic pumps, and external services

valves to work with for parts. What are the appropriate pressure and return ports on the tractor? I assume I will be able to switch back

and forth between the loader hydraulics and the chute hydraulics for snow removal purposes via the selector lever and/or the aux services

control knob but I am unable to find any literature on this.

Steiner Tractor parts (and others) also sell a Hydraulic Valve Adapter Kit to run external hydraulics and I am curious if this is

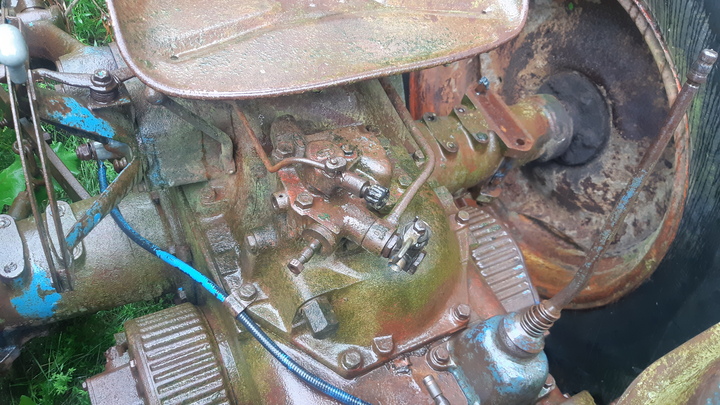

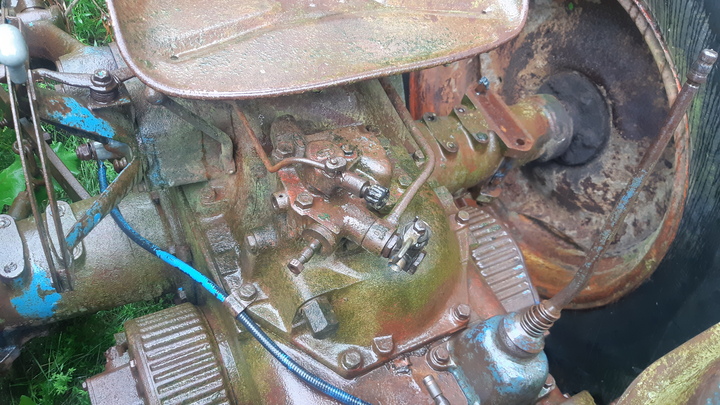

something I will need. I have attached a photo of the top cover on my parts tractor. It seems this has had external hydraulics plumbed at

some point in time.

Any help is appreciated.

acquired for the tractor.

I have a front end loader setup with four dual acting cylinders and an external directional control valve, a dual acting PTO mounted wood

splitter, and a PTO mounted snowblower with dual acting cylinder for the chute.

I am not entirely sure how to plumb the system. I have two complete FSM 3pt hitch lift covers, hydraulic pumps, and external services

valves to work with for parts. What are the appropriate pressure and return ports on the tractor? I assume I will be able to switch back

and forth between the loader hydraulics and the chute hydraulics for snow removal purposes via the selector lever and/or the aux services

control knob but I am unable to find any literature on this.

Steiner Tractor parts (and others) also sell a Hydraulic Valve Adapter Kit to run external hydraulics and I am curious if this is

something I will need. I have attached a photo of the top cover on my parts tractor. It seems this has had external hydraulics plumbed at

some point in time.

Any help is appreciated.