Good morning and thank you for your response Majorman. From all my reading here I had hoped you would chime in as you seem to be the authority on these girls.

I will go longer on this one if you are willing to read a little.

I set out last fall to buy a Diesel 40 - 50 hp basket case to fix up so I could plow and fit the 40 acres of land I have left fallow for the last 20 years up here in western NY. My dad and I picked the Super Major as it was the same model tractor he had used as a young man on the farm, and we both fell in love with its uniquely British looks. You can almost see the bulldog the designer was looking at when he drew her up.

I have been a mechanic for most of my life, so fixing her has never been a fear of mine, My motto has always been anything can be repaired up to the cost of replacement, and since a new Tractor that can do what this one will do would run 30 grand or so I've got some wiggle room.

So, to answer your questions. I polished everything with a extremely light polishing compound meant for removing swirl marks from paint on cars somewhere in the neighborhood of 3000 grit. It did a nice job of removing most of the corrosion, and not much else. I will admit though that I appear to be 3rd or 4th in line attempting to repair this, the 3pt arms had obviously been removed decades ago and had to be "found" when I brought her home. so I have no clue what the last owners did, but there is obvious evidence of heavier hands... All shuttles now move freely with gravity, in other words you can hear them knock back and forth when you tilt the assembly. I used a factor service manual I found online to take everything apart, and fashioned tools as needed so no large hammers were used.

She came with a valve chest from another model, I traced the casting number to a ford 8OO series, 806 may be, (I was a parts guy for 10 years so I know how to dig) it has a pressure out and return port, that is where I measured the 1700PSI. The 3pt did nothing, so I found a correct valve chest on EBAY and bought it, along with all the parts to rebuild, (O-rings plugs and such) from Agriline across the pond. It did come to me with very contaminated aw32 in it.

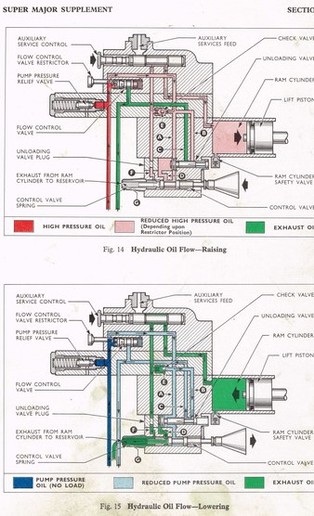

I rebuilt the new valve chest, the one spring loaded shuttle for the flow control in it was stuck, 2 weeks of patient heating and a fabricated extraction tool got it free. Polished and reassembled, I took apart the ram assembly, removed the obviously wrong o-ring from the unloading valve, polished and put back in with no o-ring. I removed the leveling valve assembly, polished gently, everything looked in order, the deflector cone on the level valve was pretty bent up, but the valve slid freely with no force so... I refreshed all the O-rings, and added fresh(and wrong) oil.

Now the 3pt arms would raise extremely slowly and 20 or 30 LBS of force could push them down. Obviously pressure was leaking into the lift ram from somewhere, but none was getting to the actual control circuit. When you pull out the auxiliary service valve on the valve chest the arms would lock wherever they were, but there was no flow out of the aux port. Also you could not hear the pump whine like I had been able to with the original valve chest. I did pull the little set screw in the chamber that contains the flow valve in the valve chest, and QUITE a bit of oil came out there. I got a bath when I cranked it and forgot to hold the shutoff for the motor... I did put the old valve chest on again, and same result, still makes pressure at the port.

SO, I tore her apart again, I appreciate that the designers balanced the top cover so nicely at the front seat mount bolt, the must have known someone would be in here a lot. This time I drained the oil again, replaced the return line filter or muffler with a new one from Agriline, the old one was paper and heavily contaminated, it reqired 30PSI to start to pass oil. Then cleaned all again replaced a bunch of O-rings again and put new aw32 again. Oh yea, I also pulled the screen from the bottom and cleaned it and the housing, everything was already pretty good but...

No change... That's what brought me here. I love a good challenge, and prefer to do the research and figure these thing out on my own, I have a 60+ hour a week high stress job and these "puzzles" are how I unwind, but after a year of off and on failures, I am ready for a lifeline.

Majorman, after I post this I am going to go grab a couple pails of "universal Tractor oil" like you recommended, I believe it is several orders of magnitude thicker than AW32 so fingers crossed, and see if anything changes. will update! The previous owner was running a log splitter with it for a small firewood business so I know the pump is at least OK.

I do not have access to another tractor to swap valve chests with, so If anyone in the Western New York or Finger Lakes area would like to chime in I would love to try that, I have a new gasket and O-rings for you! Majorman, I would be willing to pay postage to mail it to you as well for testing. If you are in to that sort of thing. I haven't tackled getting pictures on here yet, but if that would help let me know.

I appreciate everyone who takes the time to read this, we refuse to give up on her, and honestly I need a little win right now, overcoming this problem for me would be like a kid at Christmas at this point! I also promise not to drop the ball after my problem is solved. I spend a lot of time reading different forums to see what others have done and nothing is worse than following a thread only to never know if the problem was solved or how!

Cheers!

Arne