JasErnest218

New User

My hydraulic pump blew a o-ring and was squirting fluid from the pump when using the loader. I ordered a new o-ring and changed it out. I filled up with new hydro fluid

started the tractor and no hydraulics. I tried the shot of air into the dipstick opening and still no hydraulics. What can I do to get hydraulics back?

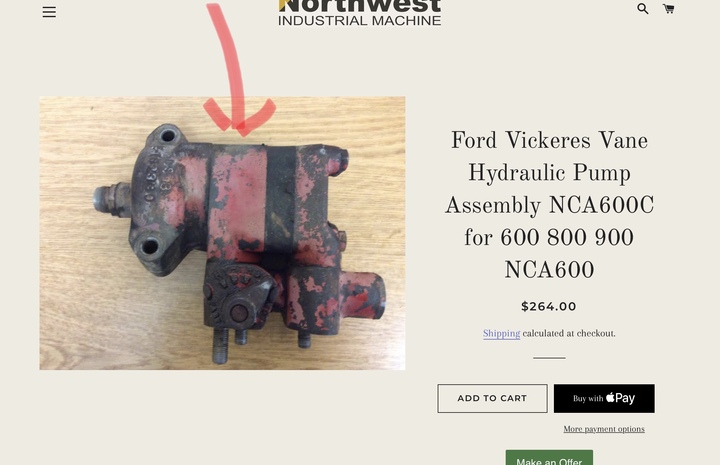

It is a vickers vane style pump exactly like this: https://nwindustrialmachine.com/products/3926

The pump was a huge pain in the butt to take on and off. 2-3 hours off and 2-3 hours back on. This was due to the lower frame that was in the way. I have a row crop single

wheel in the front.

We have a big snowstorm coming in the weekend and I need to get it back going.

UPDATE: It has been fixed thanks to everyone here. THANK YOU!

This post was edited by JasErnest218 on 03/04/2022 at 11:20 am.

started the tractor and no hydraulics. I tried the shot of air into the dipstick opening and still no hydraulics. What can I do to get hydraulics back?

It is a vickers vane style pump exactly like this: https://nwindustrialmachine.com/products/3926

The pump was a huge pain in the butt to take on and off. 2-3 hours off and 2-3 hours back on. This was due to the lower frame that was in the way. I have a row crop single

wheel in the front.

We have a big snowstorm coming in the weekend and I need to get it back going.

UPDATE: It has been fixed thanks to everyone here. THANK YOU!

This post was edited by JasErnest218 on 03/04/2022 at 11:20 am.