Good afternoon,

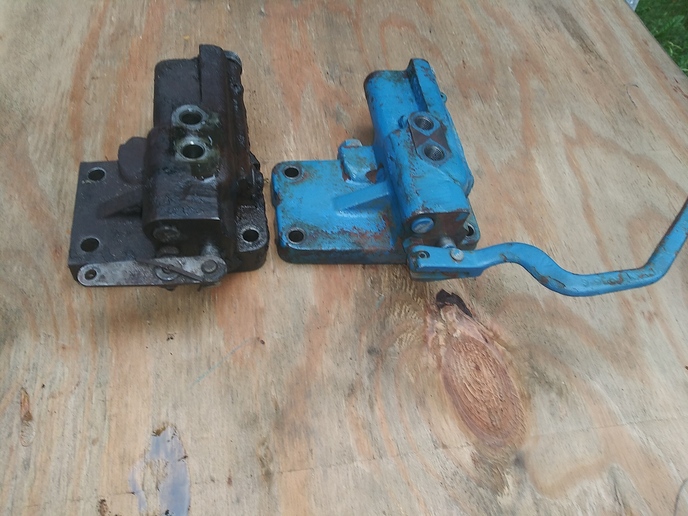

I have a 1956 Ford 860 that I am looking to put a Freeman trip loader on. The seller of the loader says I can chain down the 3 point arms, plumb the loader to the fitting under the seat with a ball valve and it will work. I would like to be able to switch between loader and 3 point without having to mess with chains if possible. Is a selector valve what I need to accomplish this? I can find one on this web site.

It doesn't say it fits an 860 but lists every other 800 series. I think it may be a misprint. Any help would be appreciated.

https://www.yesterdaystractors.com/Ford-801_Selector-Valve_E0NND960AA.html

This post was edited by bobem12 on 08/24/2021 at 09:51 am.

I have a 1956 Ford 860 that I am looking to put a Freeman trip loader on. The seller of the loader says I can chain down the 3 point arms, plumb the loader to the fitting under the seat with a ball valve and it will work. I would like to be able to switch between loader and 3 point without having to mess with chains if possible. Is a selector valve what I need to accomplish this? I can find one on this web site.

It doesn't say it fits an 860 but lists every other 800 series. I think it may be a misprint. Any help would be appreciated.

https://www.yesterdaystractors.com/Ford-801_Selector-Valve_E0NND960AA.html

This post was edited by bobem12 on 08/24/2021 at 09:51 am.