JimFord555

Member

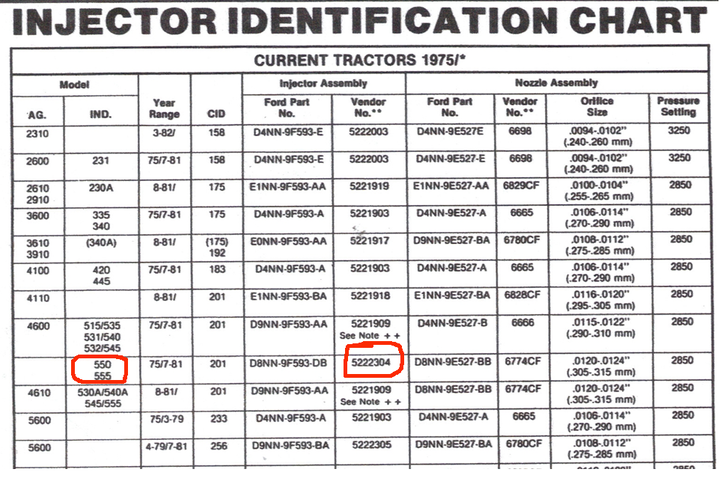

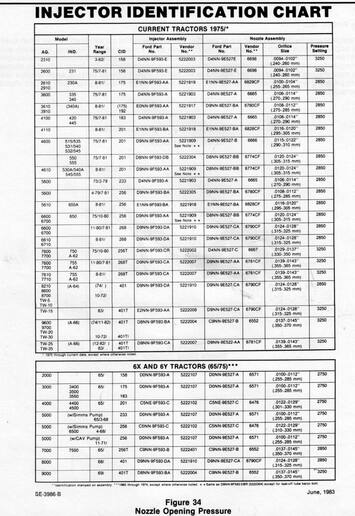

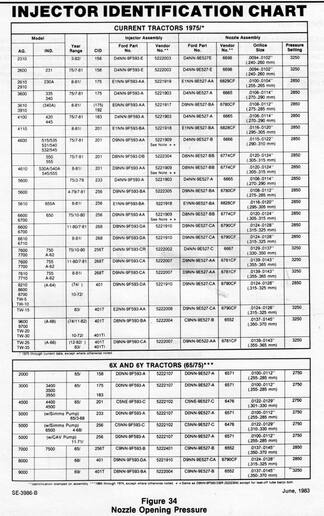

Re building the engine on my 1979 pre letter 555 backhoe that came stock with no turbo. This one has an API turbo added. It ran great from what I could tell before the hole in the cylinder (reason for rebuild) but now Im trying to decide to get rid of it or keep it. I want reliability and I plan to only run the machine on my 5 acres. I have been told that the pump and injectors in stock configuration with the turbo will add a little more power, not excessively wear the engine and burn the diesel cleaner. If i remove the turbo I need to cap off the oil lines to the turbo, re configure the air intake and weld up/ bolt the exhaust stack back onto the manifold. Is keeping the turbo a big risk ?

How can I fix the hard fuel lines that feed the injectors ? They leak at the injector pump fittings.

Pump says

Lucas CAV ser.21291SD

DPA 3233651

Since the torque converter is out I would like to service it but its welded together. Is servicing necessary ? How should I proceed ?

Here is a video of that Im into

https://youtu.be/C7TNUBurKoE

How can I fix the hard fuel lines that feed the injectors ? They leak at the injector pump fittings.

Pump says

Lucas CAV ser.21291SD

DPA 3233651

Since the torque converter is out I would like to service it but its welded together. Is servicing necessary ? How should I proceed ?

Here is a video of that Im into

https://youtu.be/C7TNUBurKoE