Josh M.

Member

- Location

- Northeast Ohio

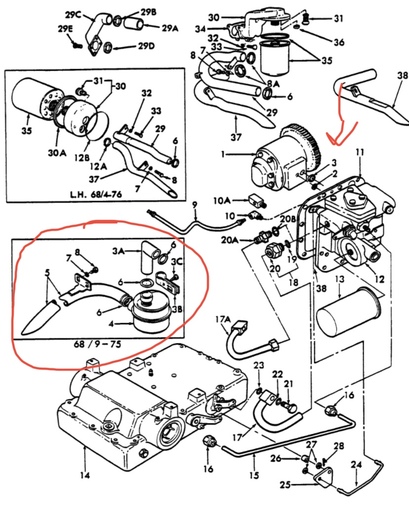

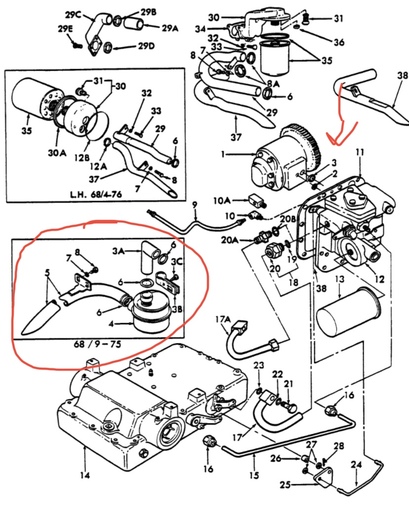

Pulled the hydraulic pump out of my 8000 on Sunday, it’s safe to say

I wasn’t having an issue with a pickup tube o-ring. The gears for the

hydraulic pump had worn into the housing a good 16th of an inch and

most of the bushings had multiple cracks in them, pto piggyback

pump had a lot of wear as well. New pump is on order but I’m

wondering how the internal filter (number 4 in the diagram) comes

out so I can replace the 3 pickup tube o-rings while I’m in there,

should it just slide off the tube? Also the number 3 o-ring on the

diagram that seals one of the outputs on the pump was completely

missing, I’m not sure if ford used a reddish color RTV sealant from

the factory but I know the o-ring didn’t fall off because there was a

tiny glob of the RTV in part of the cutout for the o-ring. As far as I

know the tractor has never had any hydraulic work done to it so I’m

not sure if it was missing from the factory or not.

I wasn’t having an issue with a pickup tube o-ring. The gears for the

hydraulic pump had worn into the housing a good 16th of an inch and

most of the bushings had multiple cracks in them, pto piggyback

pump had a lot of wear as well. New pump is on order but I’m

wondering how the internal filter (number 4 in the diagram) comes

out so I can replace the 3 pickup tube o-rings while I’m in there,

should it just slide off the tube? Also the number 3 o-ring on the

diagram that seals one of the outputs on the pump was completely

missing, I’m not sure if ford used a reddish color RTV sealant from

the factory but I know the o-ring didn’t fall off because there was a

tiny glob of the RTV in part of the cutout for the o-ring. As far as I

know the tractor has never had any hydraulic work done to it so I’m

not sure if it was missing from the factory or not.