Hi everyone. Ill get right to it.

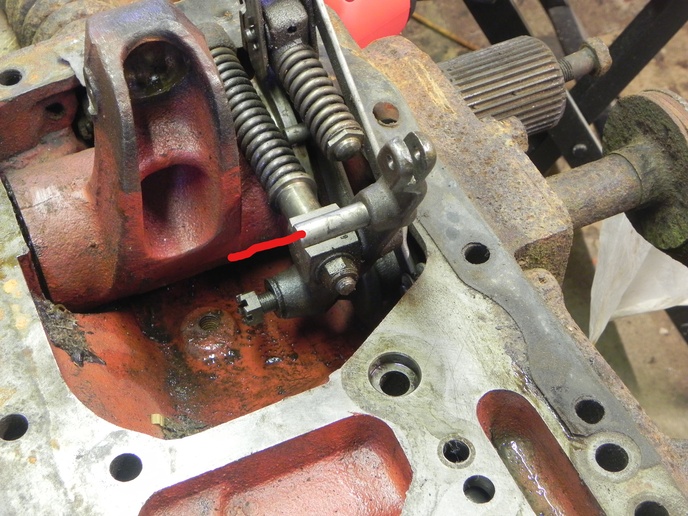

I have a Ford Powermaster 841 Diesel. The rear lift arms were not lifting all the way. I removed the lift cylinder assembly and performed the following adjustments: first the main control spring adjustment, then the constant draft (.395-.397), and then position control (.448-.450). I made sure to have the lift stop in place when adjusting the upper range of the control lever.

I Put it all back together and now, the rear lift arms lift to the top.

I noticed that when I tested the lift travel of the arms at idle that when the lift hits the top, a slight load can be heard being put on the engine. My first thought was, This thing is still trying to build more pressure, even after its in the full lift position.

Now Heres the problem. After about an hour of using the tractor, I noted fluid starting to leak. The rear lift arms were left in the full up position while I was working, as I was loading and hauling dirt with the bucket and not using the rear attachment. When i got off to inspect, It was hydraulic fluid coming from the hydraulic pump. The pump was so Hot that I couldnt touch it, and the gasket had blown out on the tail end of the pump, as well as the o ring now beginning to leak from the other end of the pump body. The system essentially is now overheating from what I suspect is either a result from something I did wrong with the adjustment, or a faulty pressure relief valve?

I dont know if the hydraulic pump was getting hot before I made the adjustments, but Im assuming not this hot if it was. Hopefully someone can help me out, because Im not certain.

Gasket kit is on the way, but I know it will blow again if I dont correct the problem. Thanks!

I have a Ford Powermaster 841 Diesel. The rear lift arms were not lifting all the way. I removed the lift cylinder assembly and performed the following adjustments: first the main control spring adjustment, then the constant draft (.395-.397), and then position control (.448-.450). I made sure to have the lift stop in place when adjusting the upper range of the control lever.

I Put it all back together and now, the rear lift arms lift to the top.

I noticed that when I tested the lift travel of the arms at idle that when the lift hits the top, a slight load can be heard being put on the engine. My first thought was, This thing is still trying to build more pressure, even after its in the full lift position.

Now Heres the problem. After about an hour of using the tractor, I noted fluid starting to leak. The rear lift arms were left in the full up position while I was working, as I was loading and hauling dirt with the bucket and not using the rear attachment. When i got off to inspect, It was hydraulic fluid coming from the hydraulic pump. The pump was so Hot that I couldnt touch it, and the gasket had blown out on the tail end of the pump, as well as the o ring now beginning to leak from the other end of the pump body. The system essentially is now overheating from what I suspect is either a result from something I did wrong with the adjustment, or a faulty pressure relief valve?

I dont know if the hydraulic pump was getting hot before I made the adjustments, but Im assuming not this hot if it was. Hopefully someone can help me out, because Im not certain.

Gasket kit is on the way, but I know it will blow again if I dont correct the problem. Thanks!