Tractorcedric

Member

- Location

- Garland. Utah

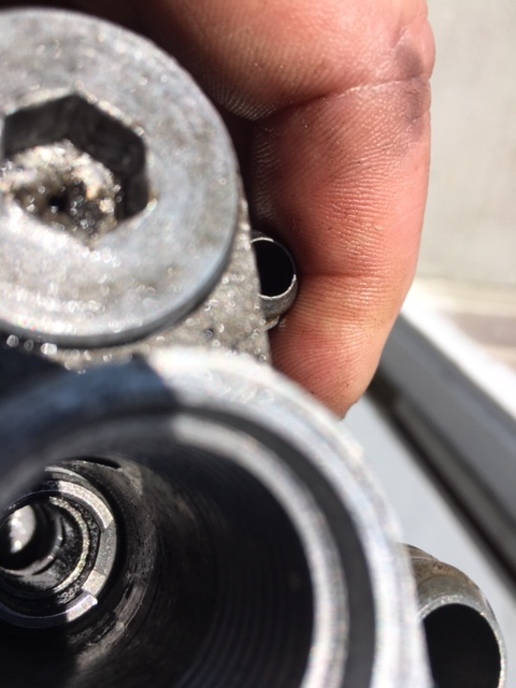

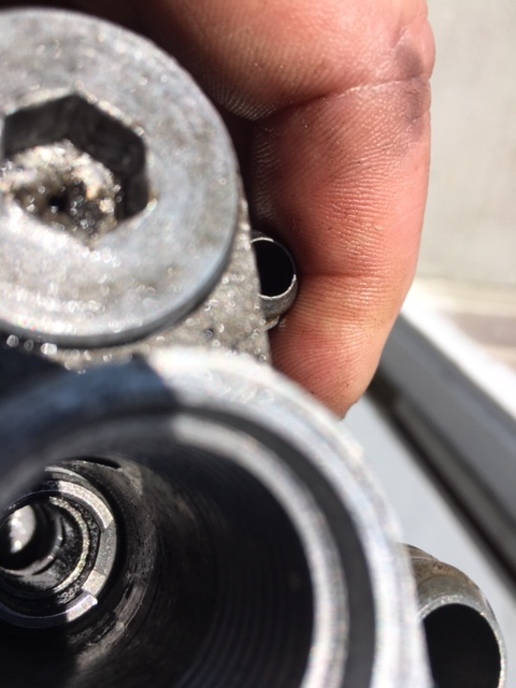

So I have the tractor split and I decided to take a closer look at the oil pump control valve. Because it was now easy yo get to. The service manual said to make sure that the orifice between the pressure and lube spools was not plugged. As I was checking it out I noticed that the steel sleeve for the pressure spool had a piece missing. Like someone had tried to remove it and it broke instead of unscrewing. Hope the picture worked. If someone had backed it out some, would that change the pressure? I had this tractor all back together once and the dual power worked, but the pressure readings were low.